Modeling – The Present – Version 5, The Casper Layout

This page shows current construction on the layout. The most recent entry is at the top, and they get older as you scroll down.

8 February 2026

I did a lot of work since the last update in late December.

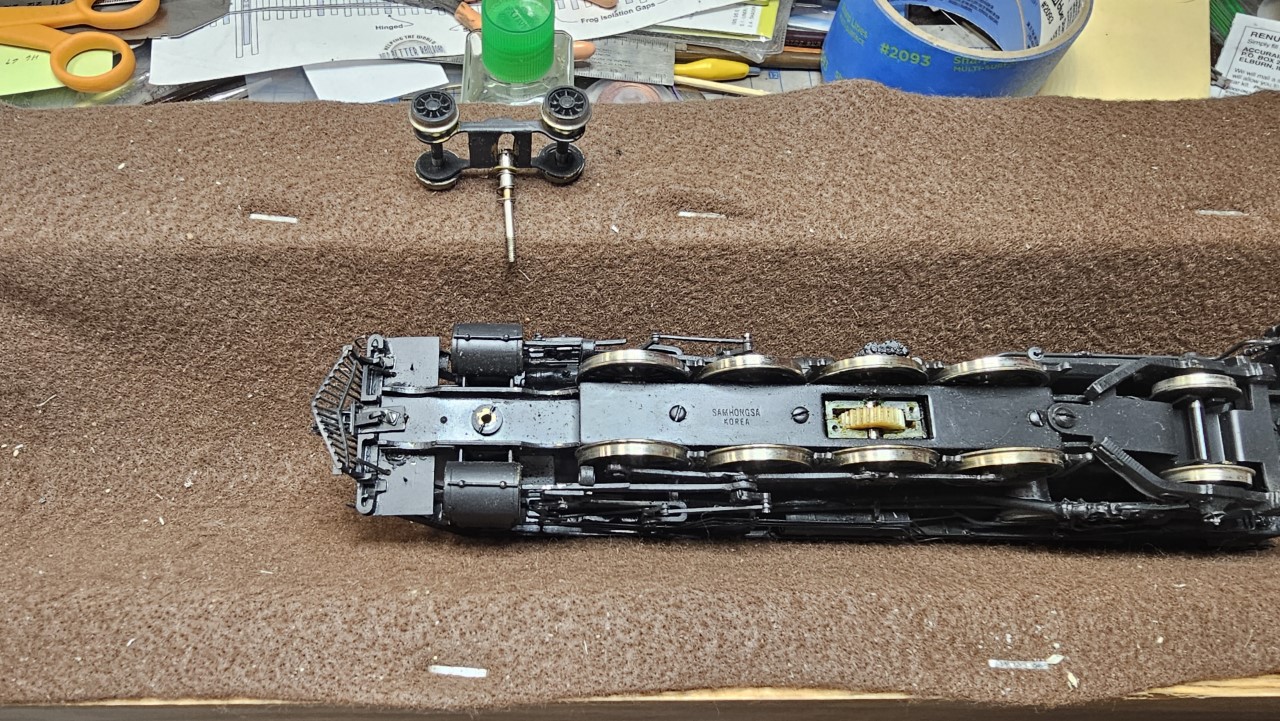

That turned out to be a bigger project than I was expecting. The last time the loco ran was probably 35 years ago. It ran great at that time, but during the years the loco was packed away the grease in the gearbox hardened. When I tested the loco on straight DC before starting the conversion, the motor tried to turn but the drive train was frozen! I would have to fix that as well as do the conversion.

Initially I planned to put the decoder and speaker in the usual place - the tender. But when I tried to disassemble the tender all I found in the bottom of the can were a few holes that were way too small to fit the electronics into.

If I was careful I could cut larger openings that the spine of the car would hide once reassembled, but I decided to investigate the possibility of putting the decoder and speaker into the boiler. So I started disassembling the locomotive.

As usual I took photos of every step along the way. Here I've removed the pilot truck.

When I inspected the boiler I was amazed at how much room there was inside, even with the weight installed.

I've been wanting to try out one of the Boiler Barker speakers available from Scale Sound Systems in one of my locos, and when I looked behind the smokebox cover it looked like there was plenty of room to install one. I ordered a couple of different sizes.

I test fitted the decoder and keep-alive in the boiler. In this shot the keep-alive is above the weight and can't be seen at all. The decoder also partially fits atop the weight. What is left sticking out has plenty of clearance above the gear tower. I wouldn't need to put anything in the tender except one connection wire for power pickup.

On January 3rd I posted my latest layout update video.

With the speaker for the P-2 on order and the mechanism awaiting cleaning, I turned my attention to building the next phase of Cody on the layout - the marshaling yard for Husky refinery.

As of January 3rd, this was the view of the lower level looking from the Vocation side through the peninsula and over to the Husky refinery.

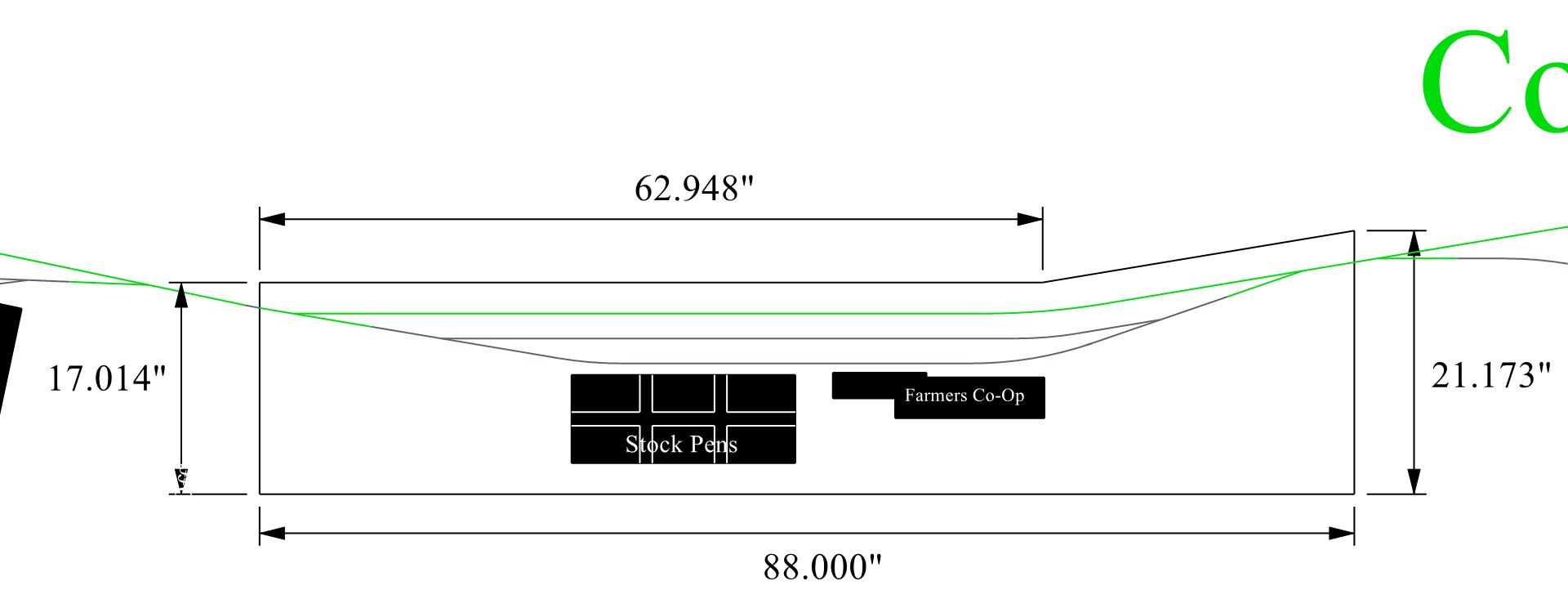

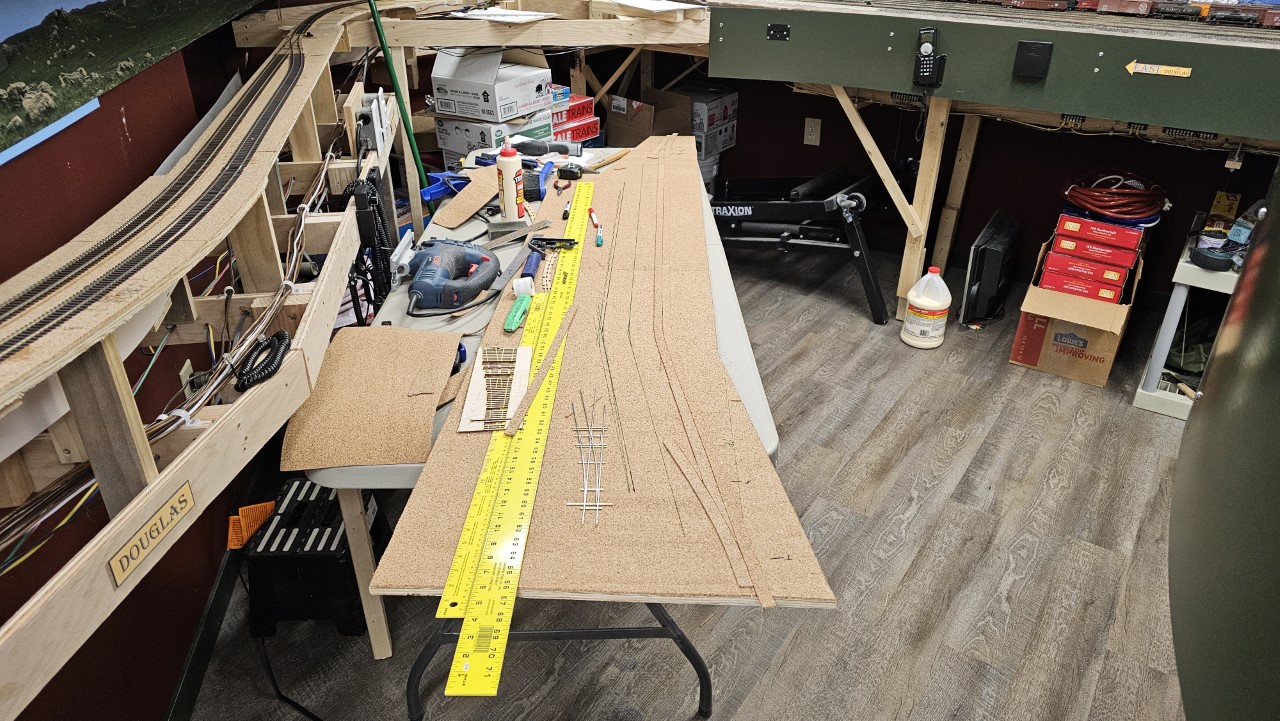

Once I had the exact position of the track at the interface defined, I took the yard back to the table yet again. By January 10th I had the second of layer of cork installed for the roadbed for the mainline, and I marked out the centerlines for the yard tracks. You can see that this was a bit of trial and error, as I had to make adjustments for the turnout geometry.

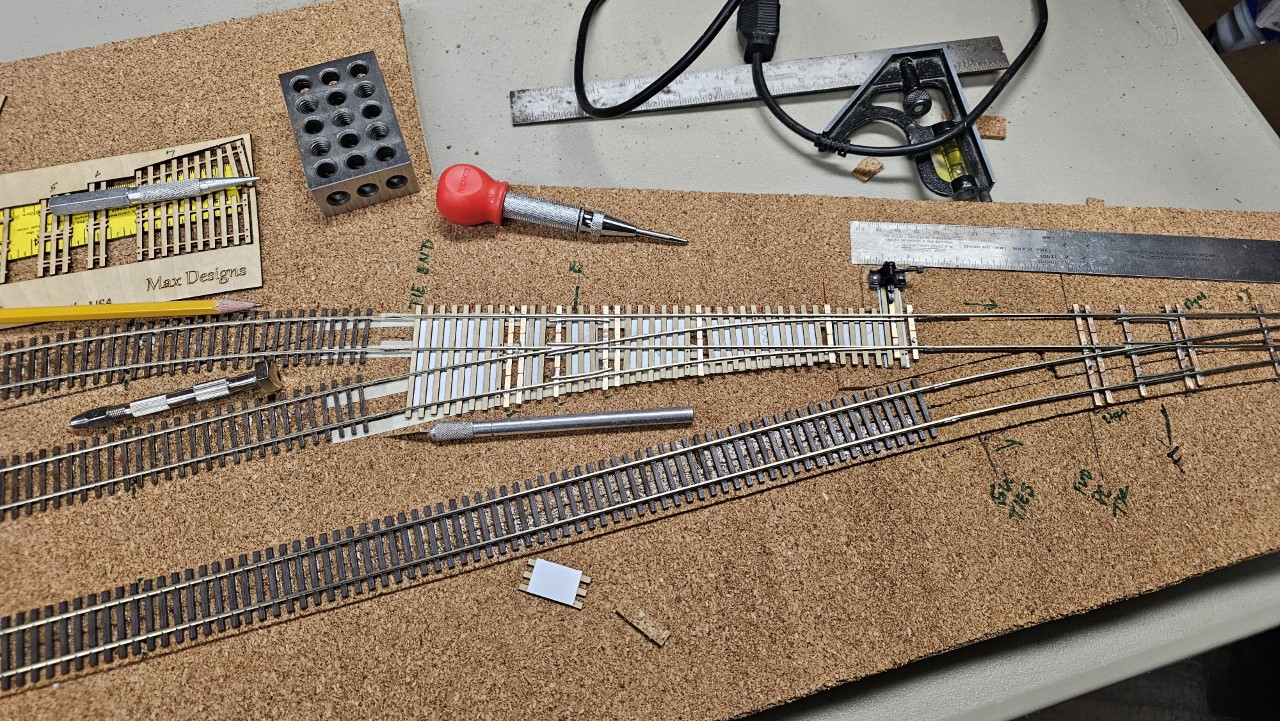

Here's a close-up of that turnout installed across the joint. If you look close at the first PC board tie to left of the joint you can see that this turnout is secured in place using a flathead wire brad. The other end of the turnout is also secured with a brad. This thing can't be allowed to shift at all or equipment will have a problem staying on the track through here.

At this point I took a break from yard construction to tackle another job - installing lights for the lower deck. It occurred to me that it would be easier to work on Cody with more light. So the first step was to install the panel for the switch to control the lights. This is exactly the same as the one for the sections of the main deck below the upper deck, over near Douglas. The installed switch/dimmer on the right side is for the lower deck lights, while the empty box on the left is for the power switch that will someday control structure lighting power supplies for Riverton and Thermopolis.

Over the next few days I installed all the lights, with a break of a couple days while I waited for some two-foot LEDs to arrive. During that time I worked on tracklaying in the yard, but we'll get back to that.

On the 17th I finished installation of the lights on the Vocation side of the peninsula. Here's Vocation all lit up:

On January 18th I posted a video about installing the power switch and outlets for the lower deck lighting.

On the 20th I posted a video about installing the lights themselves.

I was pretty sore after crawling around under the layout for several days. That plus some non-railroad stuff kept me away from the layout for a few days. I didn't get back to work until around the 22nd. However...

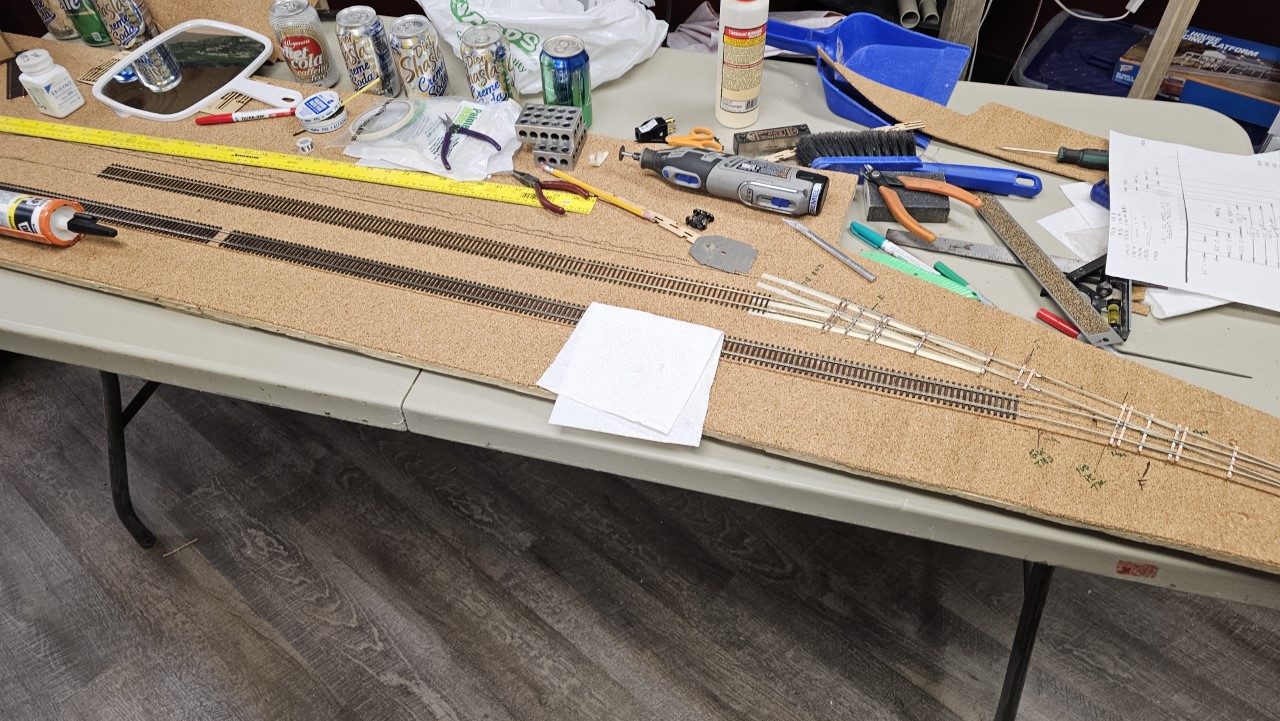

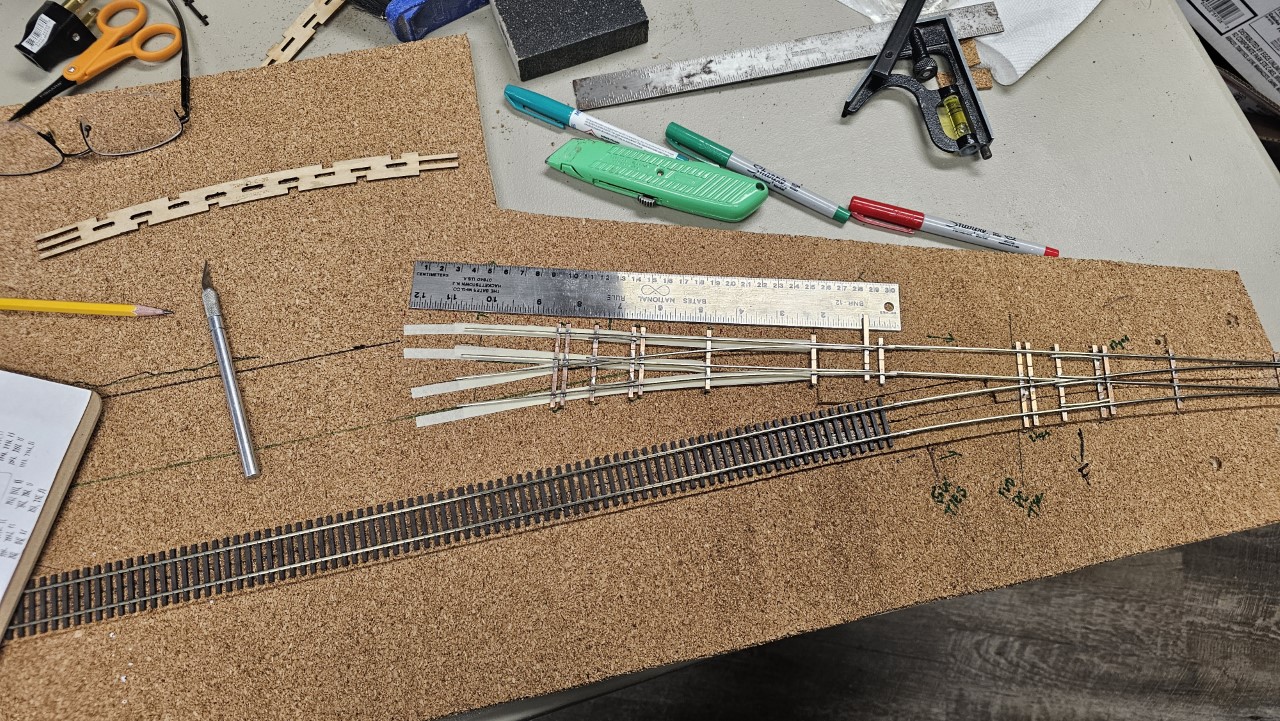

While I was waiting for the two-foot lights to arrive I did do some work on the yard on the 17th and 18th. Here, on the 17th, I'm installing the ladder turnout at the east end of the yard. This, the turnout at the other end, and the yard tracks are all code 55.

Late on the 24th the yard went back onto the layout, this time for the last time. The connection to Husky was glued and screwed in. Over the next few days I added risers and leveled the yard, then connected all the tracks to the power buss. The only thing left is to run a train into the yard, and into Husky, to test everything out. I have yet to do that.

On February 3rd I posted my latest layout update.

The evening of the 7th, after everything had several hours to dry, I reassembled the gearbox. I added a touch of oil to all the bearings and a bit of teflon-laced grease to the idler gear and worm. I didn't glop it on the way someone had in the past - just enough to wet the surfaces.

Then I reassembled the motor and gearbox and applied power to the motor. The assembly ran freely.

Now I just need to clean up the geared driver, where the grease had oozed into the bearings and made it very stiff.