Casper Construction Progress Part 2 – 2023 – April through June

26 April 2023

The last four weeks have been pretty busy. Here we go!

On April 3rd I published Layout update #41.

On the 10th of the month I went to Basin to visit Dave. We worked on some 3D printed caboose steps for him, and also built some of the chain link fencing for Rocky Mountain Drilling.

With the new spur installed and wired, I posted a YouTube short of the first delivery of hoppers to the new mine.

On the 14th to the 16th my wife and I went to the North Platte Train Show with some other members of the Casper club. While there I sold several diesel locomotives and the 130' turntable and roundhouse I've been lugging around with ne since I lived in South Carolina! I was sure glad to get rid of that thing!

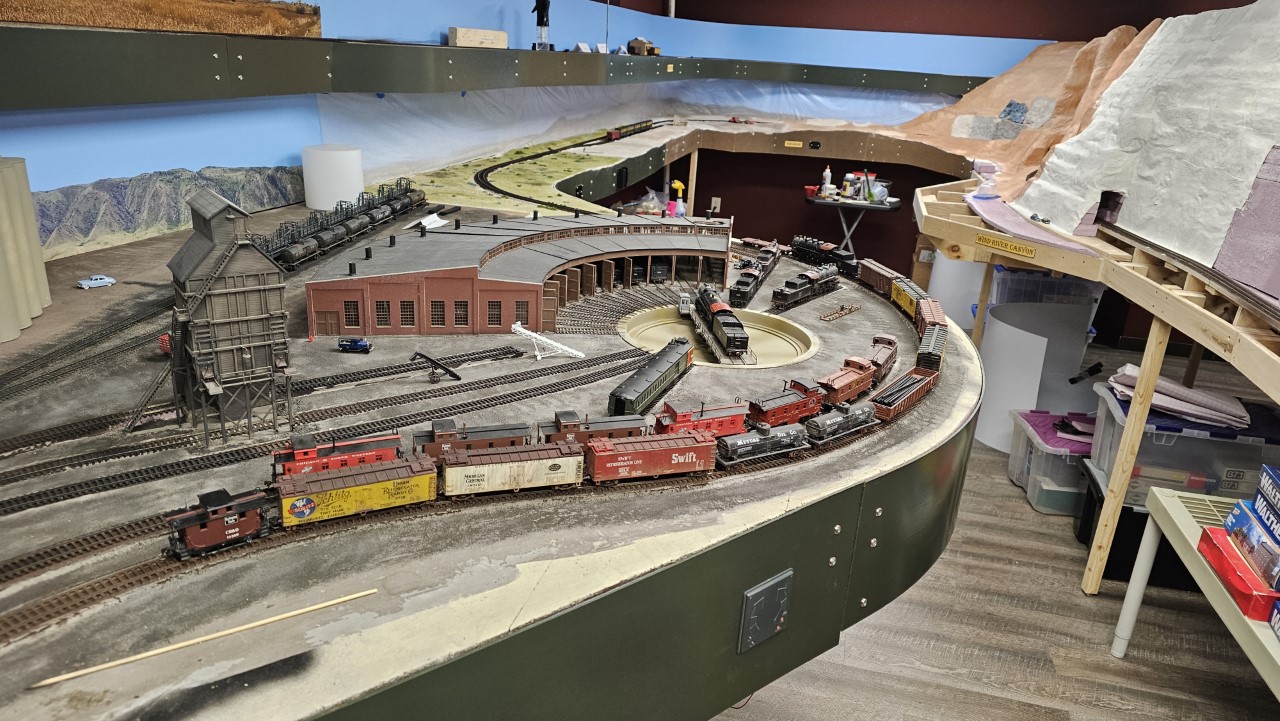

Since I had to stop frequently to let glue dry on the pens, I bounced around doing other small things on the layout. Here we're looking back towards Rocky Mountain Drilling and Todd Brothers. If you look closely to the right of Todd Brothers behind the green truck, you can see that I've installed a long section of chain link fencing. Dave made this section for me when I went to Basin on the 10th.

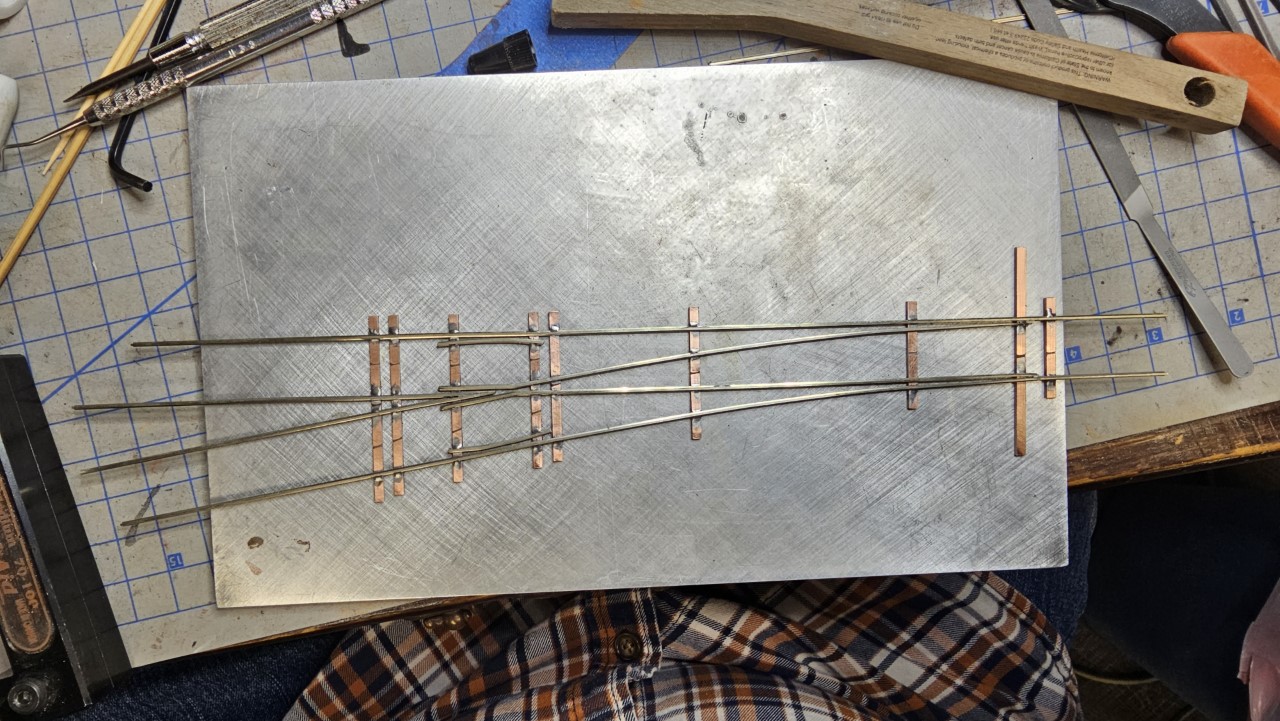

Yesterday evening I finished up the deck, and today I painted the ties and the steel deck itself. The paint is dry but not hard yet. Here the deck is sitting on two machinist blocks to let air circulate all around it, and I laid the ties on top to take this shot. In a day or two I'll start on the trusses themselves.

And finally, today I put the two houses in their rough spots near Rocky Mountain Drilling. The white house still needs a roof, and the bigger house still needs a chimney and weathering. I need to finish scenicking this area before I can extend the trackwork east towards Douglas, because I won't be able to reach this area easily after that track is in.

26 May 2023

Long update this time...

On May 3rd I published Layout update #42.

The first bit of subroadbed in Greybull went on later that day. Initially it was installed as a single piece right across the swing gate, to ensure the heights matched. It would be a couple of days before I cut the subroadbed apart, so meanwhile I crawled under the gate to get in and out of the train room.

By the 13th I had the gate subroadbed cut away from the Greybull piece, so I could swing the gate open again. I first cut it on the 12th, but the cut went the wrong direction so I had to build a repair patch to correct it. You can see the repair patch just to the left of the final cut if you look close.

On the 15th I started cutting out the subroadbed for Greybull. By the 17th I had the main section at the north end cut and laid on the framework, with the old Orin yard throat I'd kept from the layout in New Jersey fitted into place. Everything will be lifted to the correct elevation with risers later.

I'd received the bridge parts from Central Valley on the 22nd, and by the 24th I had the completed truss structure painted and the bridge essentially complete. I still have to permanently mount the rails on the deck, but that will come nearer the time I install the bridge near Lander. For all the challenges this kit offered, it came out pretty good!

Putting down the sheet cork in the wide end of Greybull was a real pain, because I had to lean over and squeeze between the Greybull and Lander benchwork. Laying decent track, especially at the back where the track to staging would be descending on a 2% grade would go, would be very difficult. So I spent a few minutes and simply disassembled the Lander benchwork in that area. It was much easier to work in Greybull after that.

15 June 2023

This is the second time I've had to add this update, thanks to WordPress (which is the CMS I use) bugs. Site may go down for awhile if I can find a better service.

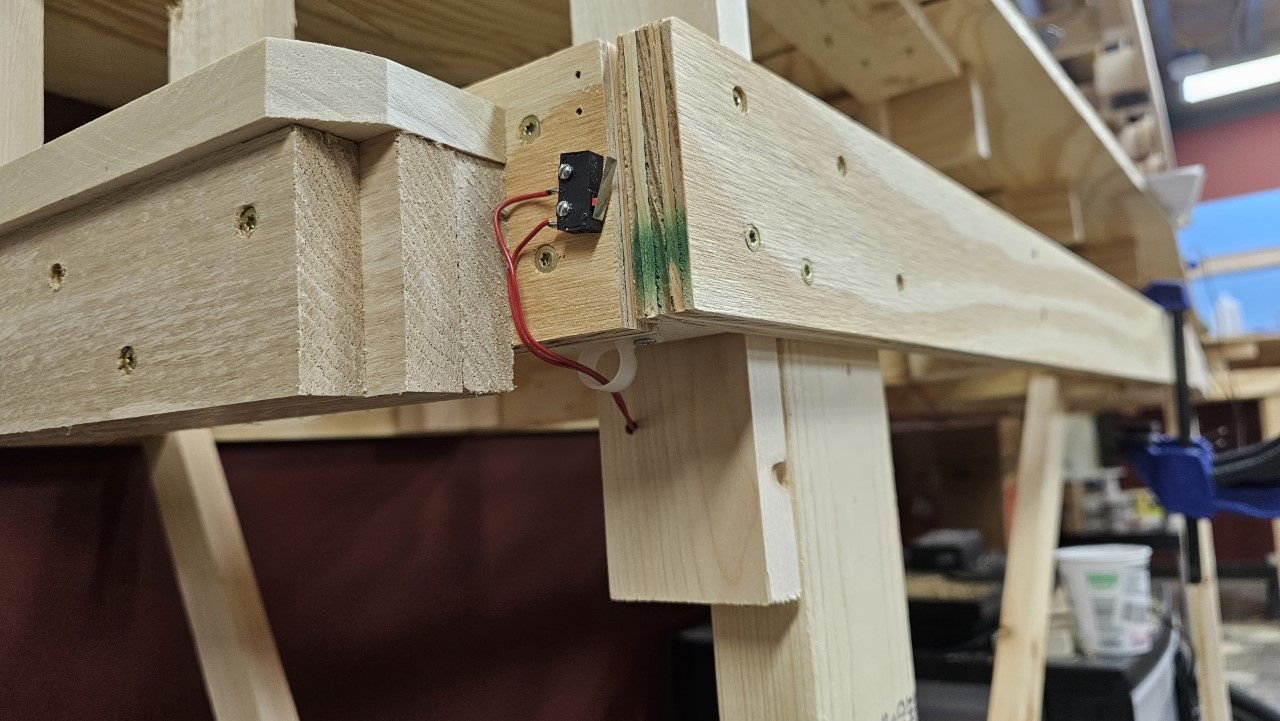

On the 1st of June I finished phase 2 of the gate wiring - installing switches to act as interlocks to turn off power to the gate tracks and approaches from both ends, to prevent a train from running off the track and onto the floor when the gate is open. Here's the switch that controls track power on the gate itself and the approaches from the hinged side of the gate.

On 3 June I posted my latest layout update video.

Work has continued on Greybull trackage, with construction of a couple of new turnouts (one of which was installed on the swing gate) and laying of the Greybull passing siding. I also started adding the new buss wires for the staging tracks.

On the 13th my wife and I drove over to Douglas, where I took a series of photos to stitch into the Douglas backdrop on the layout. Here's one of the photos, severely reduced in size and resolution to fit on the website: