Casper Construction Progress Part 1 – 2023 – January through March

22 January 2023

I also posted my latest video update on the 3rd:

On the 5th I had major surgery, so I was pretty much away from the trains for several days. By the 11th I was well into recovery, so I was able to resume simple work on the layout. On the 10th and 11th I installed ground throws on the mainline switches in Basin - one each day. Twenty minutes of work was about all I could manage.

I figured I could set at the workbench without too many issues, so on the 12th I renumbered an Accurail hopper. This was kinda midway through the process, and the decal sticks out like a sore thumb. It got better, but I stopped working on this because the Accurail renumber decals were braking up. I ordered some liquid decal film to coat the decals to stop the breaking up. It arrived yesterday.

29 January 2023

5 February 2023

That afternoon I started weathering the exterior of the hoppers. I start with a very light wash of black, which is Model Masters flat black thinned with a lot of alcohol.

What I didn't know was that alcohol reacts to flat clear coats, turning them white! To a greater or lesser extent, this is what most of the cars looked like.

On the 3rd I posted my latest Layout Update video:

On the 4th I was back to weathering the hoppers. On the second side I switched to using Vallejo black thinned with distilled water, and it didn't attack the flat finish on the decals. Then I began adding some rust along ribs, grab irons and such. Here's what that looked like on the sides where I applied the alcohol wash:

Today I began applying the chalks as the final step in weathering. Fortunately the chalks help subdue the edges of the decals, and the first two don't look too bad:

This is the same car I showed with the terrible whitening of the decal above. There still some whitening around the decal, but it looks more like natural effects of weather than anything else.

23 February 2023

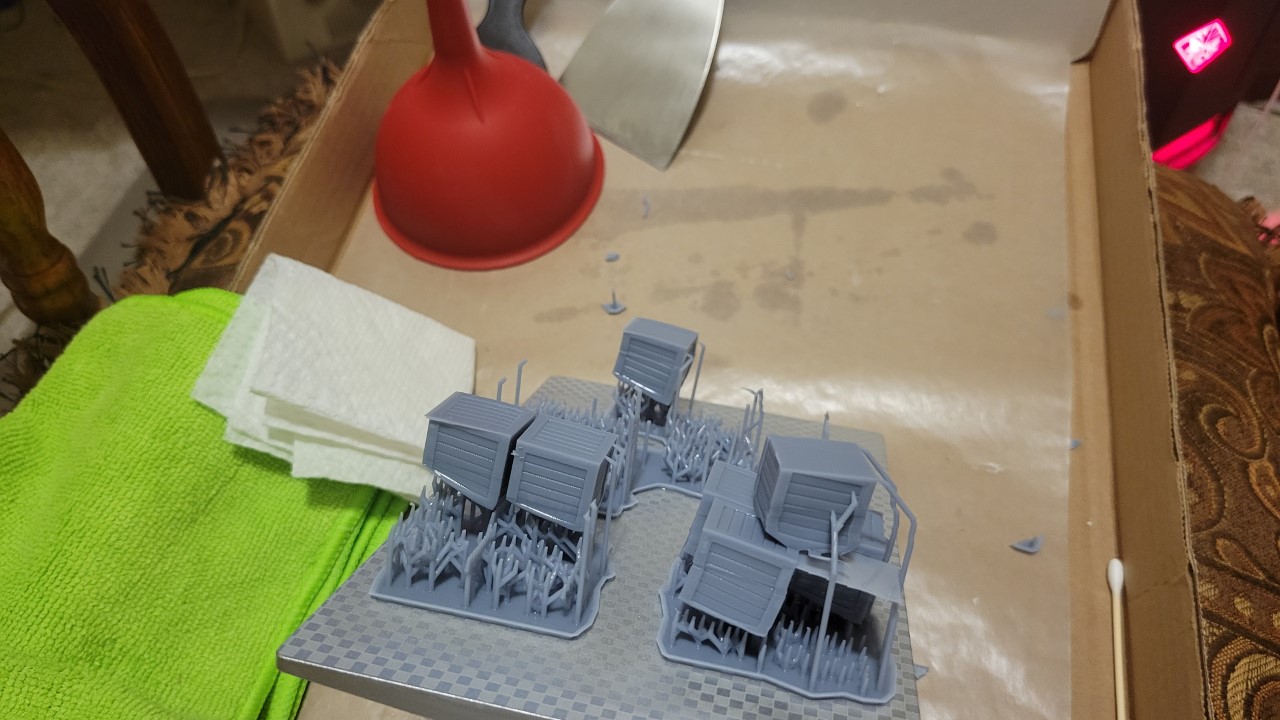

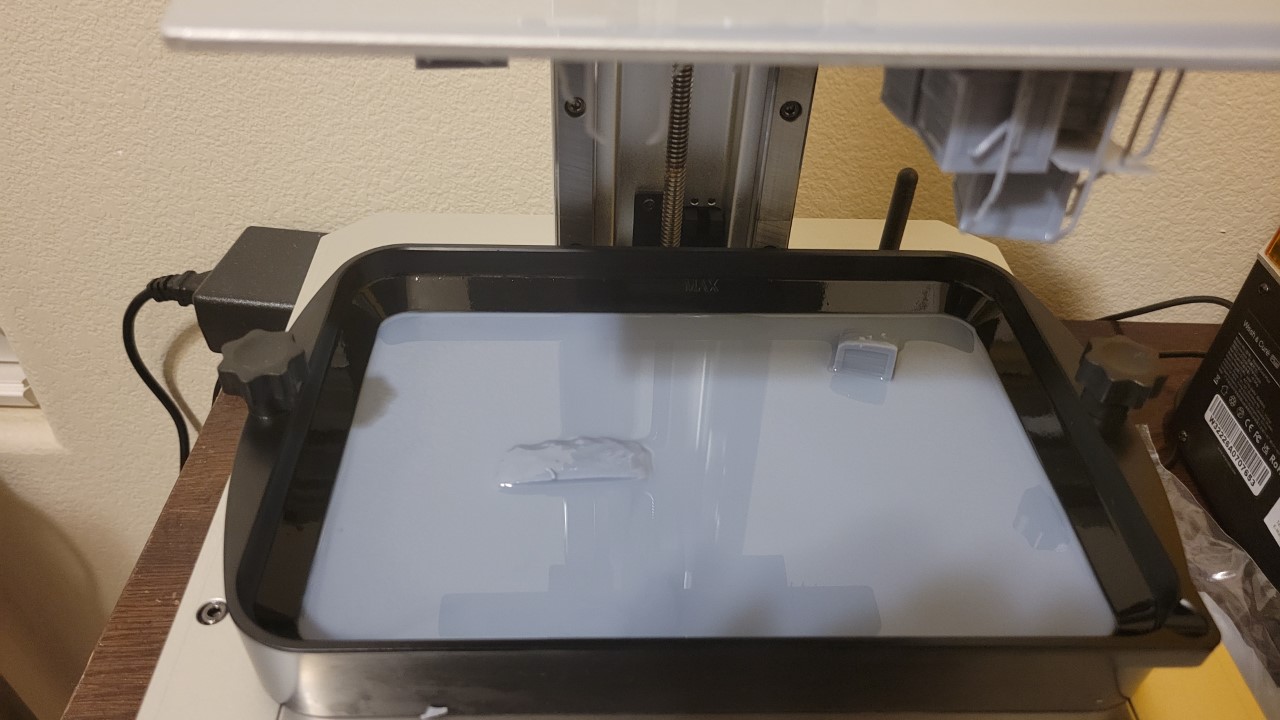

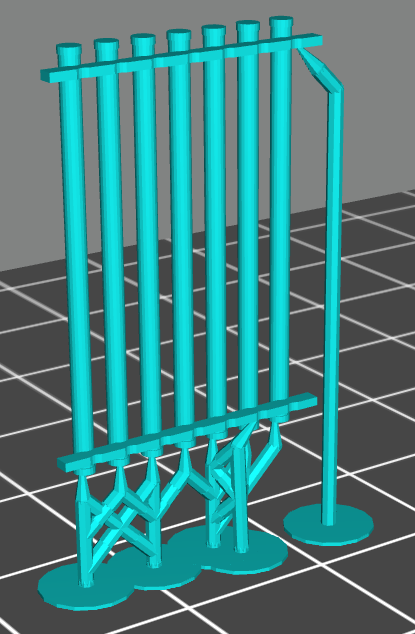

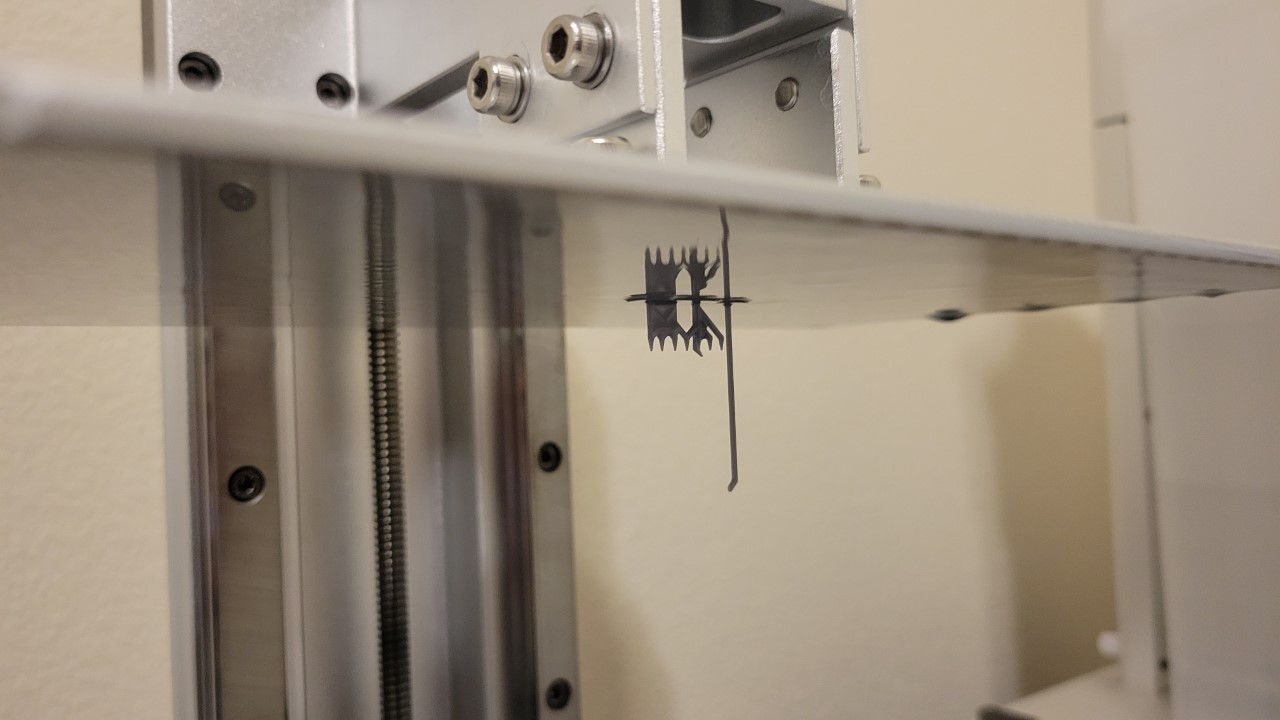

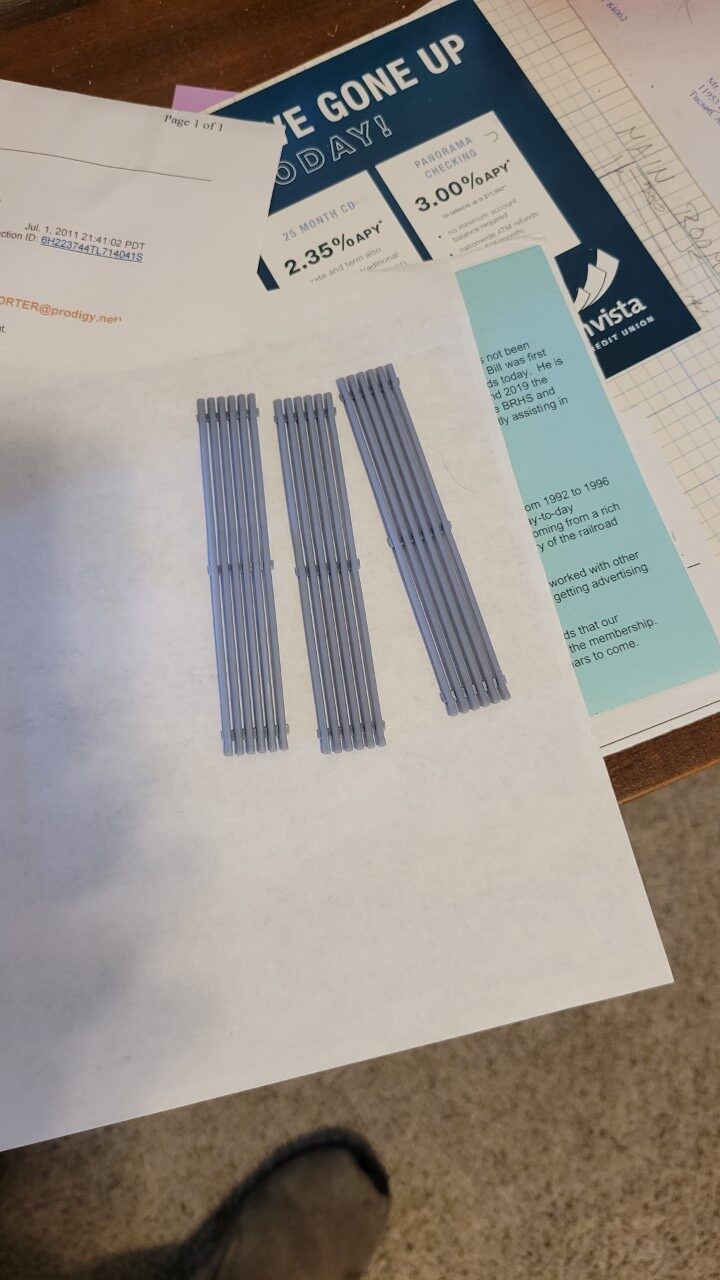

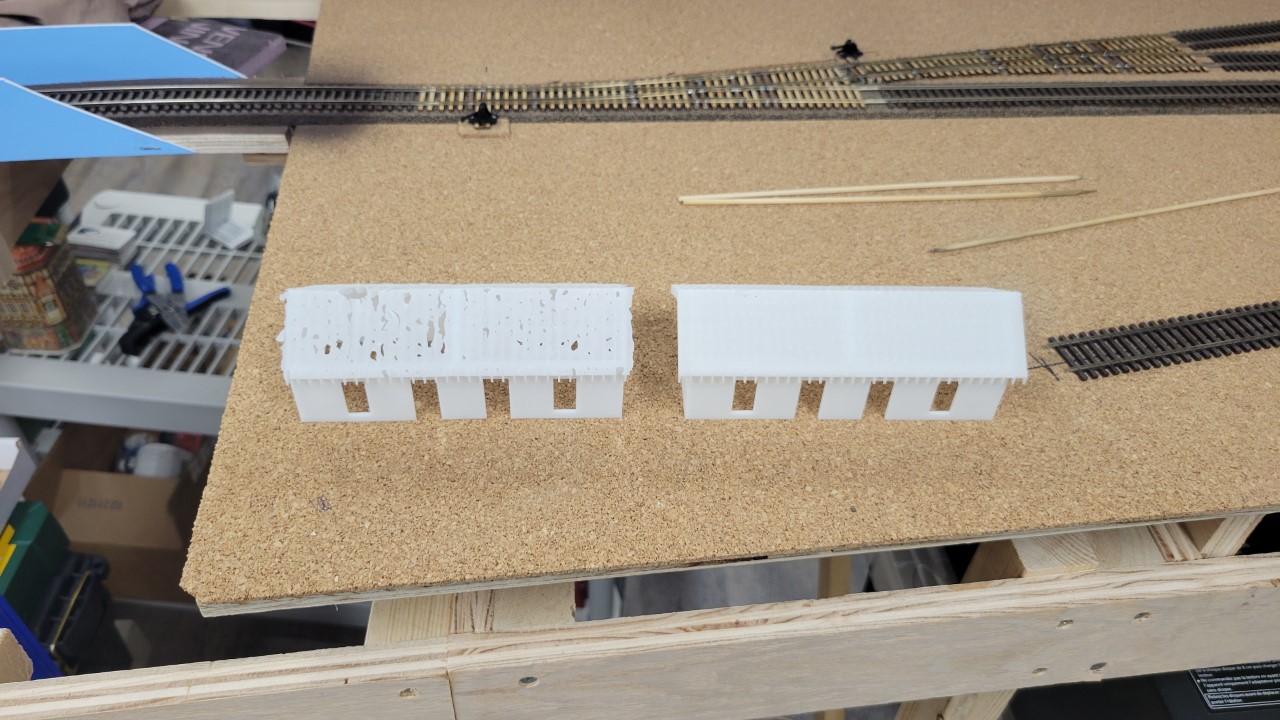

With that I was off and running! A few days later I printed out a very decent tie strip for a #6 right hand Fast Tracks turnout. I printed three of these in quick succession. They're white because that's the only resin of that type I had on hand. They'll be painted along with the rest of the track, but future tie strips will be made from black resin.

Being able to print out tie strips, which cost all of about 20 cents for the resin vs. nearly $9 for the wood tie strips from Fast Tracks, will pay for the printer over time.

Being able to print out tie strips, which cost all of about 20 cents for the resin vs. nearly $9 for the wood tie strips from Fast Tracks, will pay for the printer over time.

Walt flew home on the 19th. We had a great visit, and his help sure made building and installing all that benchwork easier!

Since new benchwork was going in, I continued working on the Lander benchwork, which is located just above Greybull. By the 22nd I had the first two sections installed. The 1X2 wood supporting the front edges is temporary. Threaded rods will hang down from the ceiling to provide support like in Riverton.

10 March 2023

On 3 March I posted the usual layout update video. This is number 40.

Yesterday I had an operating session. It went very well. A new guy, Kevin, came up from Harriman Wyoming, a small town west of Cheyenne, to see the layout and join the session. He and everyone else reported they had a good time. I was busy enough that I didn't have time to take any pictures.

Next session is planned for late June.

22 March 2023

On 13 March I posted a short video:

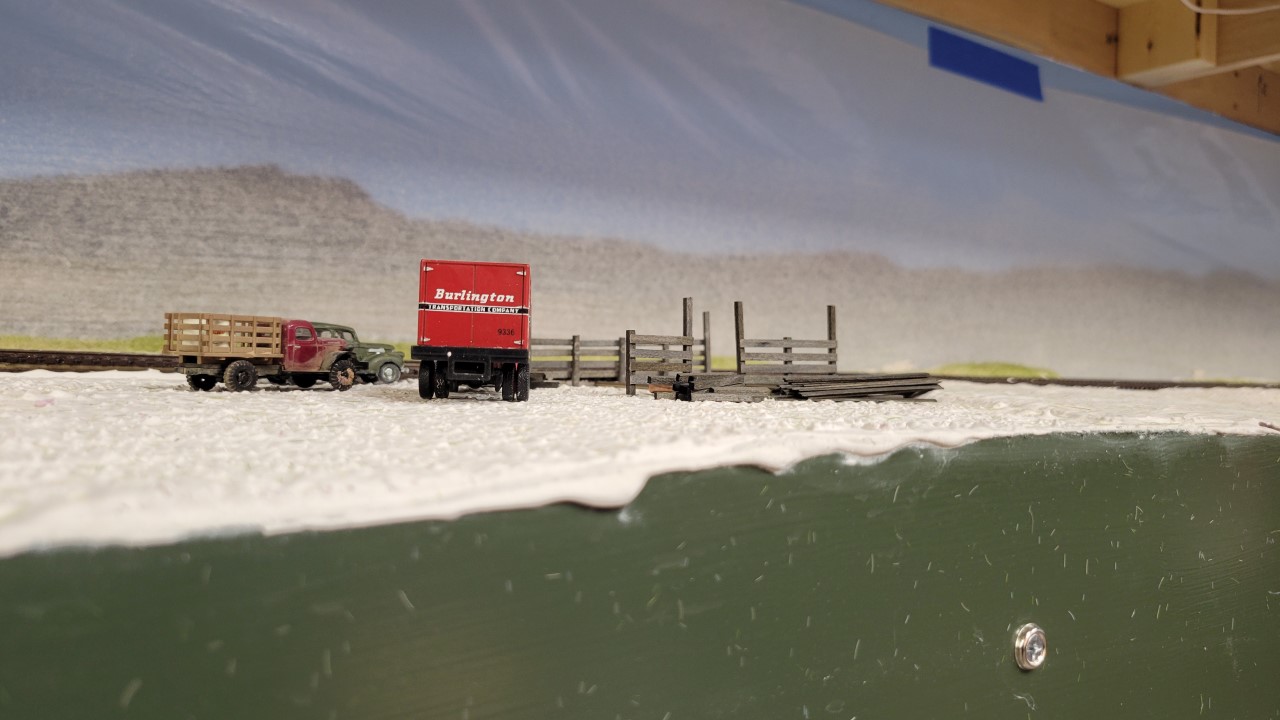

Meanwhile, over on the Powder River stock pens on the 19th - After looking over the newly applied ground cover, it seemed obvious that the ground was just too rough to be able to install the pens, so I took a bit of a left turn. I picked up a sheet of foam core board and cut it to fit the stock pen area. I'll attach the pens to the foam core, then cut out the ground where this board will sit and install the entire thing as a unit. Using the foam core will solidify the entire set of stock pens, which otherwise would be a very fragile collection of sticks.

30 March 2023

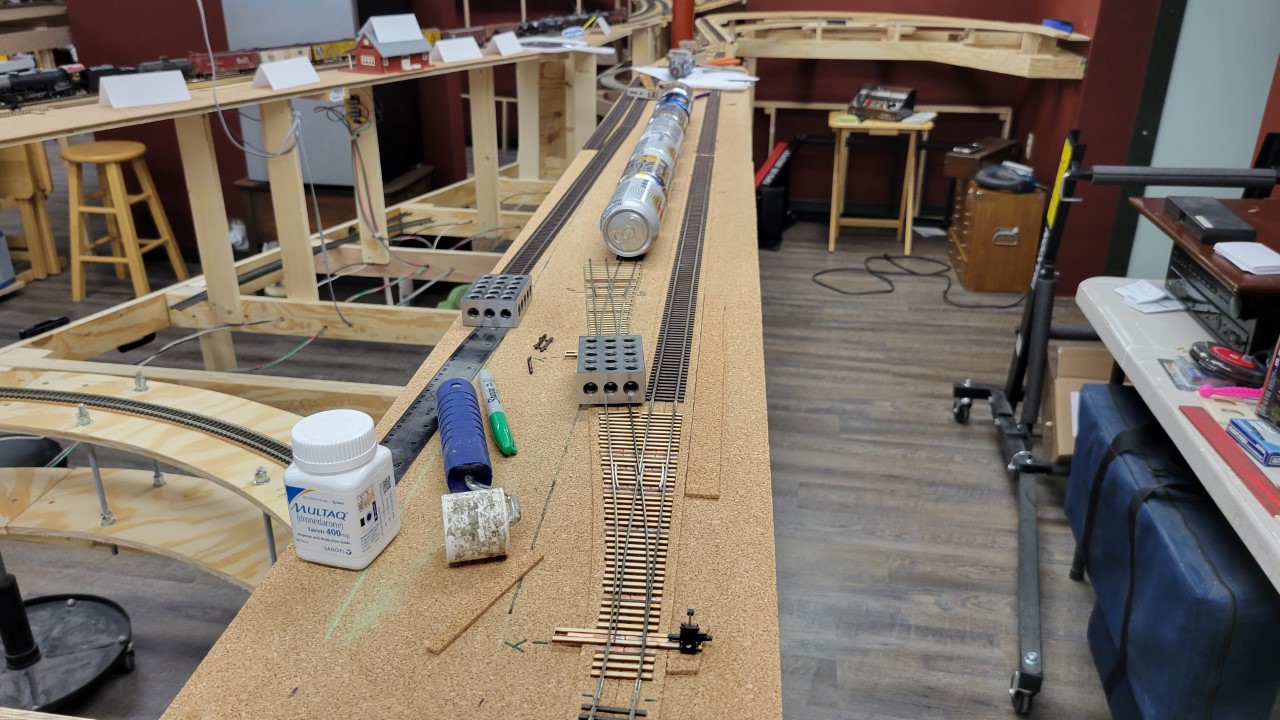

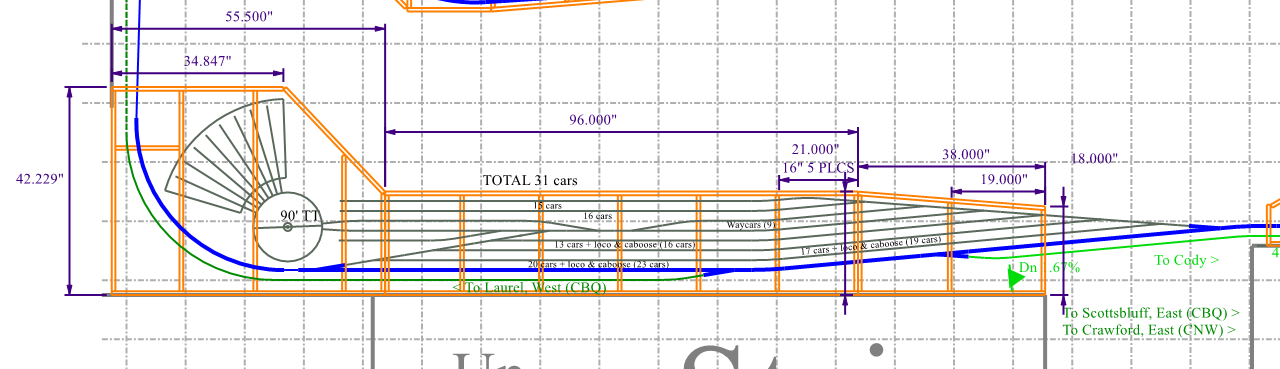

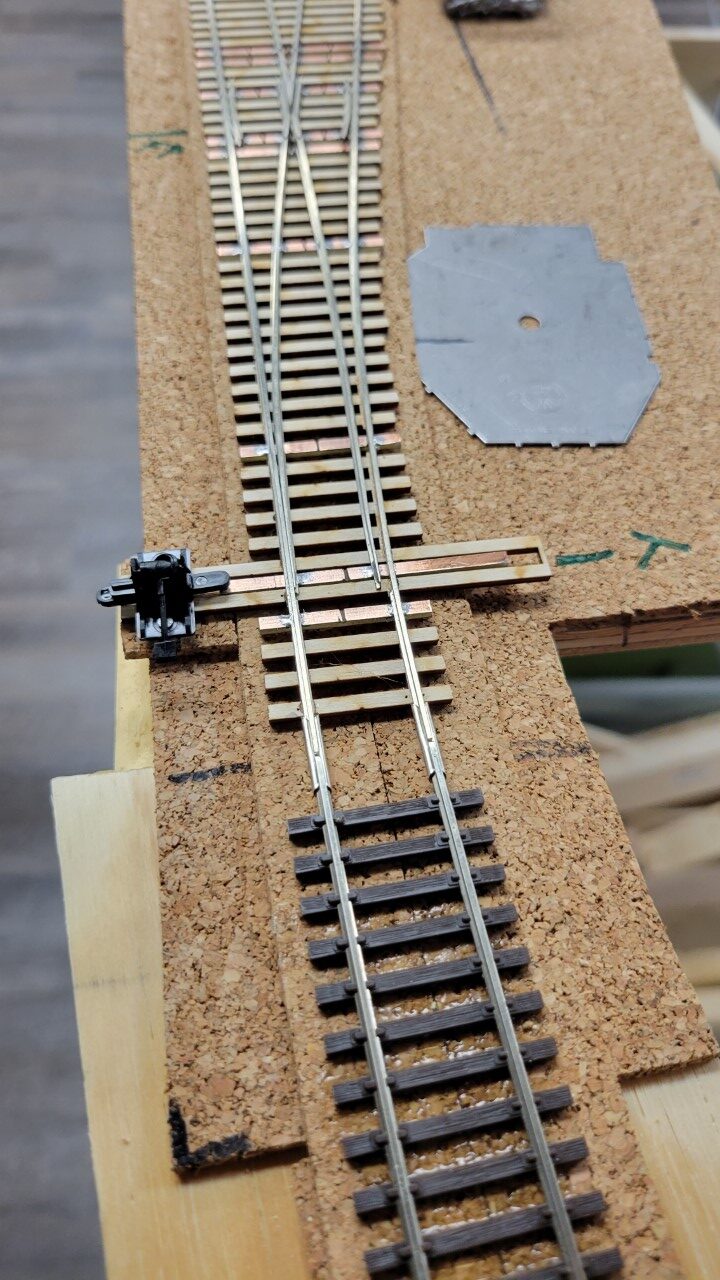

Dave from Basin came down with his wife that day, arriving about 9:30 am. Dave was here to help me modify the Casper yard throat to simplify switching of the icing platform and the industries on the east end of Casper. I'm a bit surprised that I don't have a real good shot of the area before we made modifications. This is the best one I could find.

Basically, the mainline is on the right, curving around the engine facility in the distance. The track just to the left of it, which ends about halfway around the curve, is the drill track for Casper yard.

You can see the yard ladder in the center to left part of the image, and the runaround track just behind it. The spur to the icing platform and east end industries come off the runaround at the turnout at the far left of the runaround track in this shot. That configuration meant that strings of reefers going from the mainline to the icing platform had to zig-zag back and forth from the mainline onto the drill track and then up to the icing tracks. That was a back-and-forth, back-and-forth movement for each cut. What a pain!

On top of that, the caboose track was at the opposite end of the yard, off frame in the foreground in this shot.

For a long time I was pretty sure I was stuck with this very inefficient track arrangement, because one of the basic runes of model railroad yard design is that you have to have a drill track for moving cars that doesn't interfere with the mainline.

Then Dave told me a few months ago that Casper yard, despite being a fairly substantial yard, never had a drill track! Switching was done off the main!

I'd been planning on moving the caboose track up near the yard throat in order to extend the A/D track half a dozen car lengths or more towards Douglas, since running all the way down the yard to pick up or drop off cabooses was a real pain. Then Dave made a very simple suggestion - flip around the two turnouts that tie the drill and runaround tracks to the yard ladder, so giving direct access from the mainline to the runaround track. As a bonus, the old drill track becomes a much longer caboose track, right where it's most convenient!

That's probably not real clear, but the following pictures will hopefully help.

We spent about five hours rearranging those two turnouts and replacing some short lengths of track on the runaround and the drill track. Here we've finished the work and I've added caulk to the new lengths of track. The cans are there to hold the track securely while the caulk dries. You can see where we moved all the cabooses to their new home.

I had to install three new ground throws, because while we were soldering the turnouts to the adjacent rails in their new positions, we had a bit of an accident with the soldering iron.

We touched the iron to one of the throws, and wound up with a partially melted, now non-functional throw. No big deal - it took about 10 minutes to replace it.

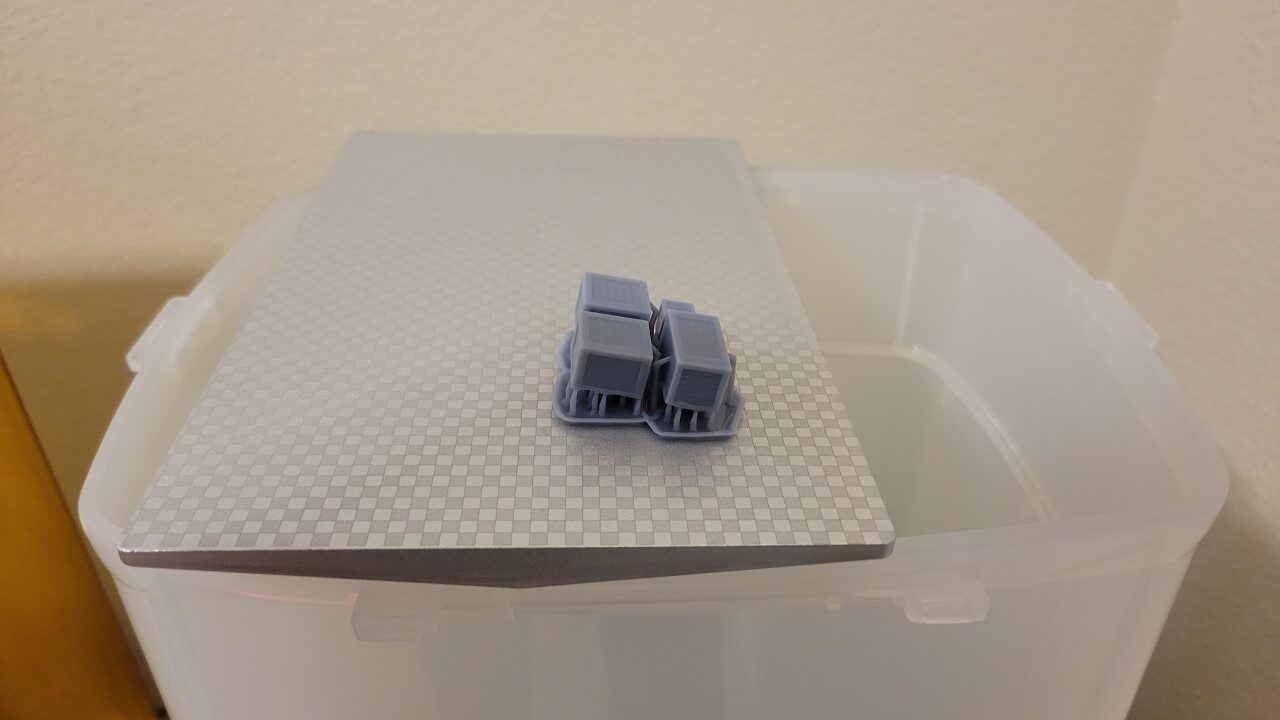

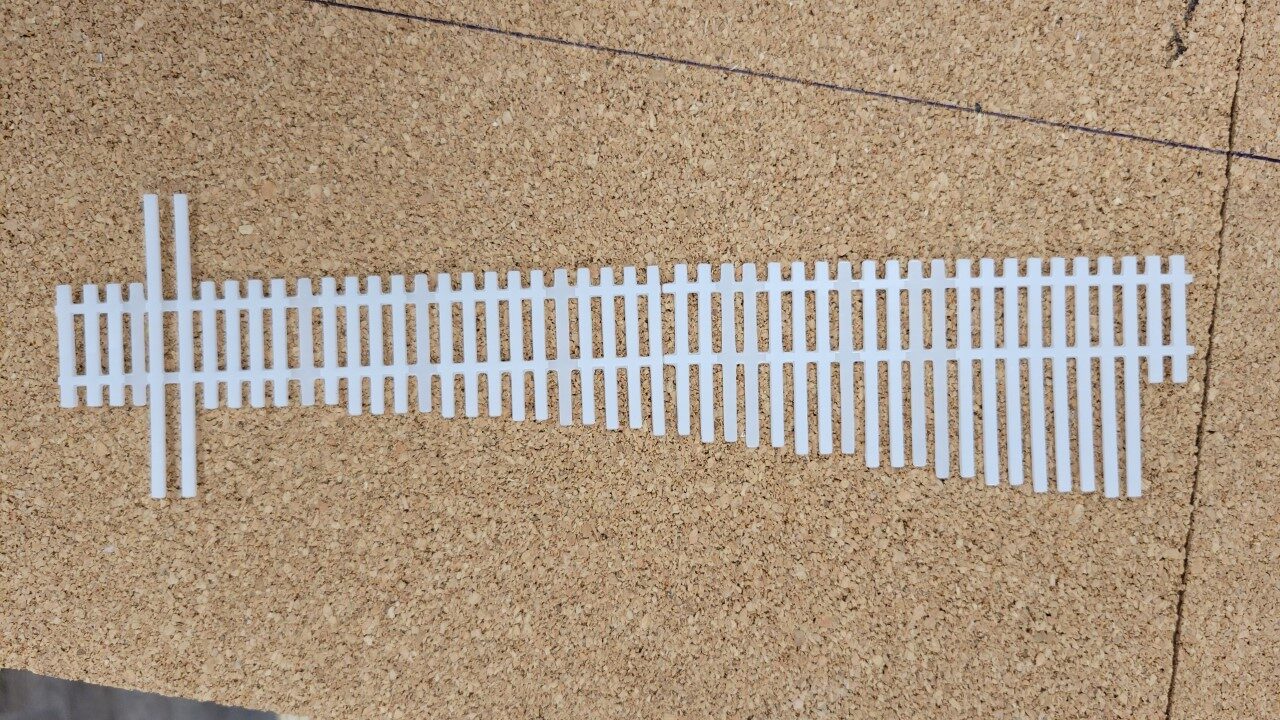

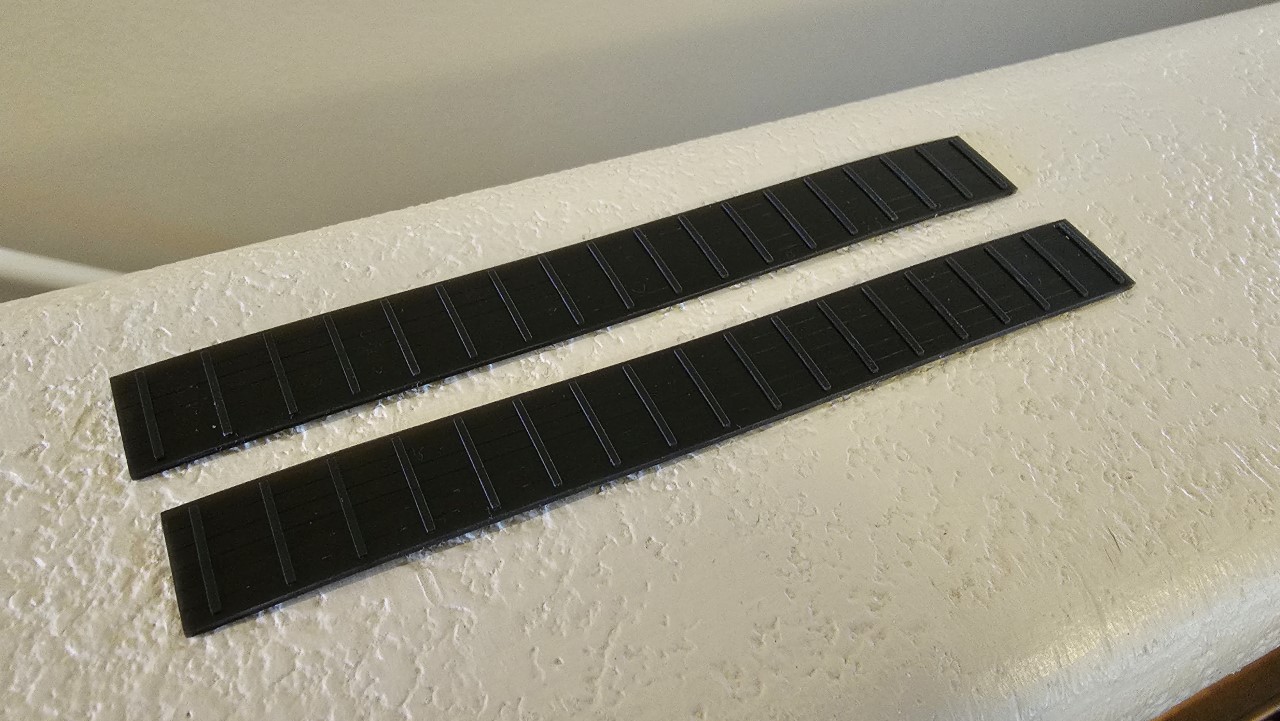

I also 3D printed floors for the loading chutes for the Powder River stock pens. These are way long - I'll cut them to length when I get to building the chutes.

I am really excited about the 3D printer - it will be of immense use on the layout and will save me a fortune over having to purchase all sorts of small detail parts.

I am really excited about the 3D printer - it will be of immense use on the layout and will save me a fortune over having to purchase all sorts of small detail parts.

On the 29th I wired the new track that extends about six feet out of Hudson, and today ran a loco onto the new track to make sure everything is okay.

The weather was above 50 degrees today, so I painted the two 3D printed houses. Here they are. Roofs aren't on yet, and I have to paint and install the door and window castings, but I think these are going to work out pretty good. They're one-print units. Larger buildings will need multiple print sessions and assembly afterwards.