Casper Construction Progress Part 1 – 2022 – January through March

1 January 2022

Here's a video I made of the first "revenue" train to run from Casper to Hudson:

11 January 2022

On the third I posted my latest layout update video.

During the first few days of the new year I also took time to clean up and inventory all my flextrack. Here's the pile of Atlas code 100 track, mostly used, when I started:

The curves in so many of the pieces are from soldered-on rail joiners where the track was in curves (mostly the giant helix) on Version 1 of the layout in New Jersey back in the first decade of this century. Most of it has not been used since. It has thousands of miles on it - New Jersey to South Carolina to New Jersey to Wyoming. I clipped off the rail joiners, which allowed the track to straighten out. This took hours to do, and my fingers were sore for a day or so afterward!

And here's all the track after I organized it.

Top to bottom shelf: ME Code 55 - just a few sticks; Peco code 70 - about half a scale mile, and a couple sticks of ME code 70 behind the Peco; Atlas code 83 - about 2 1/2 scale miles; and on the bottom shelf all that Atlas code 100 - around nine scale miles (that will be used for most hidden track on the layout, but I'm sure I have much more than I'll need)!

23 January 2022

About that same time I ordered six-conductor flat cable to fabricate my own throttle wires. I got tired of a lot of extra wire I had to keep neat from the cables I bought at train shows.

I looked all over Casper for the wire, and no one had it. Everything is eight conductor now. So I ordered 250 feet of wire from Digikey, which should keep me going for quite some time.

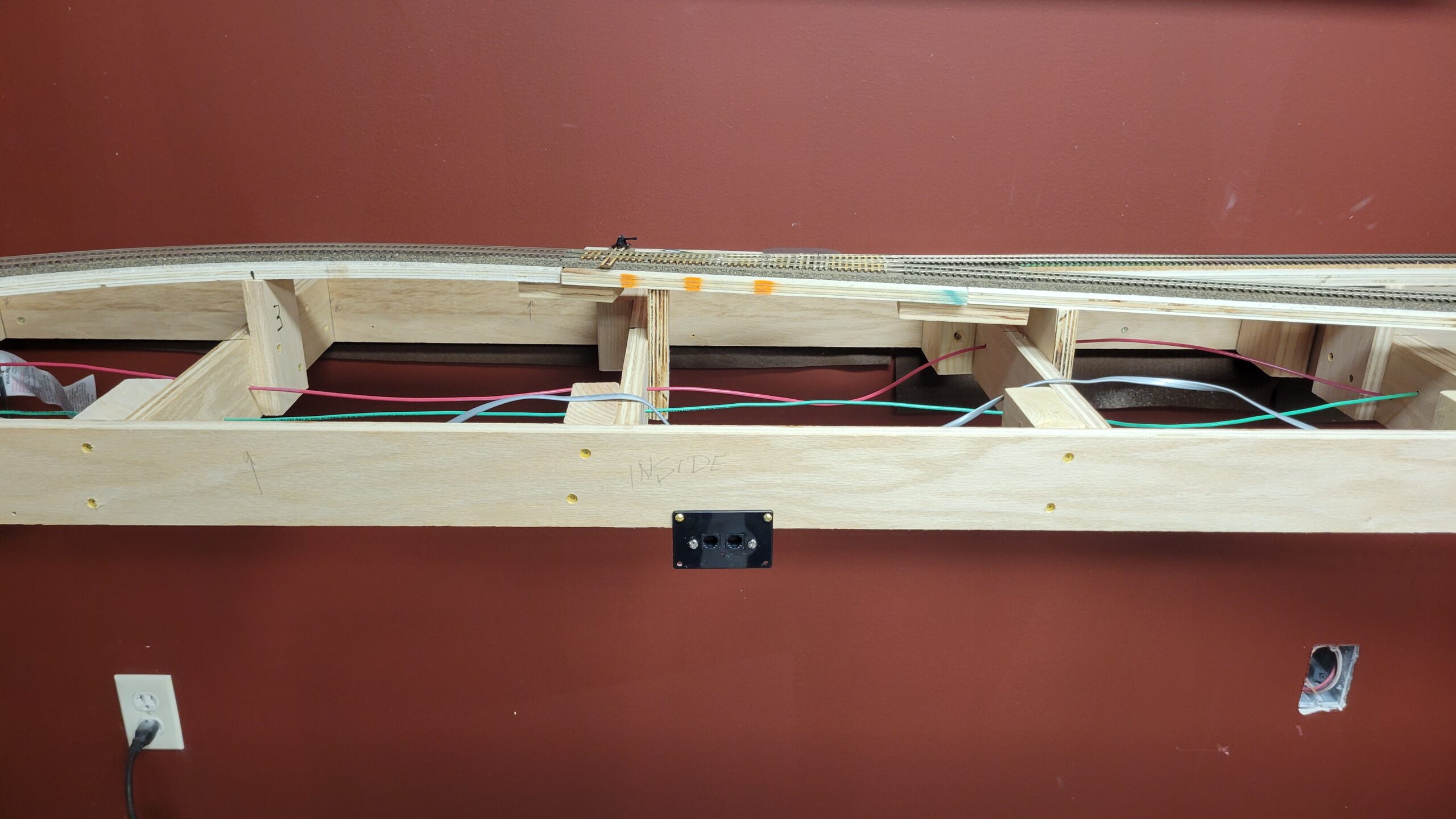

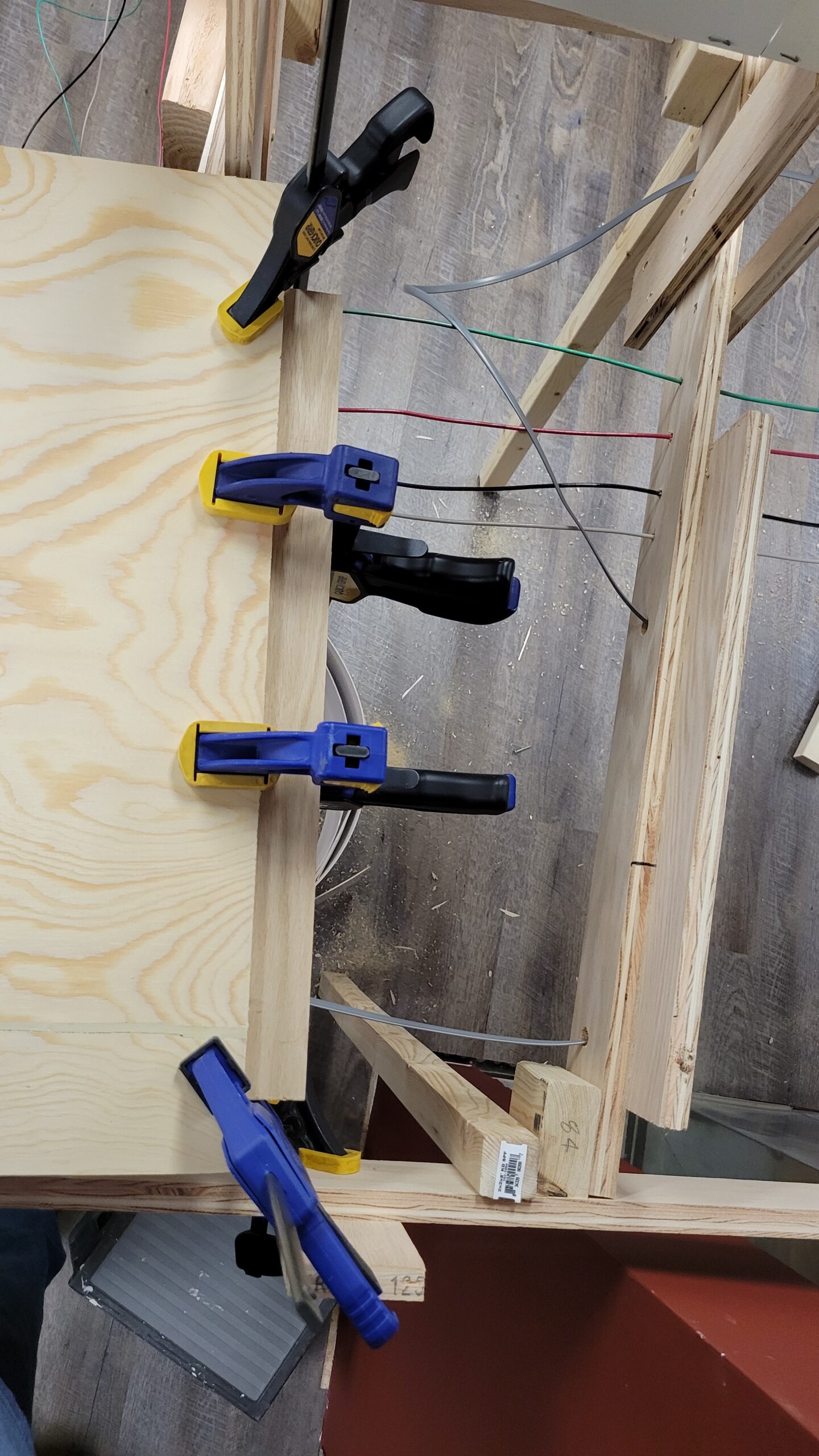

It arrived a few days later, and on the 17th I made and installed some throttle wires. I stuck the wire spool on a clamp and threaded the wire through the benchwork.

Sure is nice to not have a bunch of excess wire length the deal with! I'll go back and re-wire everything else in the next week or two.

Sure is nice to not have a bunch of excess wire length the deal with! I'll go back and re-wire everything else in the next week or two.

Tuesday I took a day and drove to Basin, Wyoming, about 3 1/2 hours away, to visit a model railroader I met through my YouTube channel. Dave lives just south of town, and we had a great visit.

He showed me his layout and we ran a local freight. I was very impressed! The layout ran flawlessly. No stalling, derailments or anything else he had to make excuses for. Here's one shot of the big, scratchbuilt Firestone tire factory on his layout.

29 January 2022

12 February 2022

On February 3rd I posted my latest layout update video.

The last few days I also started messing around with the JMRI Operations package. As part of that I photographed all my rolling stock and then entered the data into JMRI. I added the towns of Casper, Riverton, Powder River and Thermopolis, and ran a couple of passes to test out the software. It actually builds some trains to switch those towns!

Here's one of the rolling stock photos (out of a total of 78 cars at this point).

17 February 2022

This is the first code 55 switch I've ever built. I used my Fast Tracks code 83 jig, and was just careful how I positioned the rail in it. The base of the code 55 rail is narrower than the code 83 or code 70, so I just moved the rail to one side of the cut or the other to keep the rails in gauge. I checked the gauge using an NMRA track gauge.

Once I had the fascia mounted to the right (west) of Casper, I carved in some slight undulations. While table-top flat is okay in a big facility like the yard, out on the prairie it looks unnatural. Since the fascia is still pretty close to the track the variation isn't much, but I think it will really help the appearance.

I took a bit of time yesterday and mounted the turntable control into the fascia. It took a couple of hours to do this, since the control isn't really designed to mount anywhere. I had to disassemble the control box, and deepen the screws holes that attach the back so the screws would reach through the 3/16 fascia. Cutting the rectangular hole in the fascia was the easy part. But after a bit over 2 hours the control box was in and reconnected. It even still works!

Last evening I wired up all the Riverton tracks, cleaned them and tested them with a Doodlebug. This morning, in preparation for the inaugural operating session next week (really just an operations test with a friend from the area) I put industry labels along the siding, so we'll know where to spot cars.

25 February 2022

After many years of building and then deconstructing layouts, I've finally reached a major milestone - I'm ready to start limited operations! There's little scenery, but tracks to and in several towns are complete and I think I can run a respectable ops session. For several days I worked with JMRI to prepare. I entered my rolling stock inventory, towns, spurs and industries into the Operation Pro part of JMRI. I decided to use that to generate my car and train movements because I like the switchlist and manifest approach more than the car cards and waybills method.

I planned an operations test of the layout with Kurt, my friend who's face you've seen in one or two pictures helping me out with scenery, and we scheduled for Tuesday the 22nd. I did only a little construction work for a few days, instead focusing on preparing for the session and cleaning up the train room. I also checked all my rolling stock and made adjustments to trucks and couplers where needed. A couple of slightly cranky locos were pulled off the layout for maintenance.

Well, the 22nd came and Kurt was unable to make it. He'd caught a cold from his granddaughter's friend! So we'll reschedule in a couple weeks.

I was disappointed to be sure, but none of that preparation went to waste. I needed to clean the train room anyway, and the time spent entering data into JMRI would need to be done at some point anyway.

I decided to put the manifests and switchlists generated for the session to immediate use. I ran a solo operating session, putting Casper yard through its paces for the first time. I'd been planning to do a video on operating the yard for my Building Casper series on my YouTube channel, so I used this opportunity to do. The video went up last night. Here it is:

Following are several shots of the little bit of work done on the layout this past week, plus a picture or two of the layout as it was prepared for the ops session.

Dave in Basin, who I visited last month, sent me three reefers he had no use for, then sent me a big bundle of rail! He says he's finished with trackwork so has no further use for the rail. There was quite a bit of code 70 and 83 rail, plus a few sticks of code 55. There was even one bit of loose code 100 rail. Here's the bundle of rail he sent. I spent a bit of time sorting it out into stacks of the different weights. Since I was completely out of code 70 rail, this was a real godsend! Thanks Dave!

A couple days later I had the Riverton skyboard extended further, and added the final section on the lower level, running behind Shobon. I added the first layer of plastic putty at the seams, but have yet to sand them and add the final smoothing coat.

The scenery will begin building towards the ceiling to the right of Shobon, so the second level will disappear into the rising hillside just before the end of the second level skyboard.

4 March 2022

When I ran the operations test on Casper yard I identified a couple of less-than-ideal things. First, the caboose track is very inconveniently placed on the far east end of the yard, off the A/D track. Second, with a relatively short A/D track, longer through trains have to hold the main when they arrive in Casper. That's fine most of the time, but for reefer trains, which have to be iced in Casper, it's a huge problem. The geometry of the yard throat, runaround track, drill track, icing tracks and west end switch to the main is problematic.

The turnout from the main to the yard track is placed in line with the ladder, and should be placed in line with the runaround. The icing tracks come off the runaround track. so moving reefers to and from the icing track means pulling cuts from the main, pushing them onto the ladder, pulling them onto the drill track, then pushing them up the runaround to the icing tracks. Too much time consuming zig-zagging here.

If the turnout to the main came off the runaround, it would be a simple pull-then-push set of two moves to get cars to the icing tracks.

To correct the track geometry would mean pulling up and re-laying all the tracks near the yard throat, including the throat itself. That would be a LOT of work!

I came up with another solution - extending the A/D track at the east end of the yard, so those reefer trains can pull onto the A/D track. No more sitting on the main and zig-zagging cuts of cars to the icing tracks.

Here's the current arrangement at the east end of the yard. Orange lines is the benchwork under Casper. The heavy blue line is the mainline, showing the turnout off the main to the A/D track, one of the solid gray lines.

Here's the new arrangement at the east end, with the first section of extended benchwork as well. The mainline now extends another 38 inches between the east and west turnouts, and the A/D track is 55 inches longer! That will allow trains of 22-23 40' cars to pull onto the A/D track - perfect since the longest through reefer trains will be 22 cars.

Meanwhile, the caboose track will be moved over just off the runaround between the drill track and the inbound turntable lead.

With the realignment of the east of Casper now planned out, I started working on the benchwork extension, and decided to just continue with it through Douglas. Here's the first section, the Casper extension, in place except for a support leg. My camera tripod was pressed into service to support the end of the new benchwork temporarily.

I was ready to start developing the Douglas track arrangement, so on the 26th I drove over there to do some on-site research (Douglas is only about 45 miles away). Neither the Douglas Pioneer Museum or the Railroad Interpretive Center had any useful information on rail-served industries in the area, so I drove around town and photographed buildings that were obviously connected to the railroads in some way. When I got home I pulled up my Sanborn maps of Douglas and matched the buildings I'd shot with the one shown on the maps from the 1940's. Here's a couple of them.

This is the trackside face of the CB&Q freight depot. To the right, mostly out of frame, is the passenger depot.

A few blocks south of the depots, still on the CB&Q tracks is this building. The Sanborn maps call it an "IMPL. WARE HO". I think that means an implements warehouse, but I couldn't find anything more on it. It might have been some sort of farming / ranching implement business, and with the tower in the center and that pipe coming down into the main roof, may have handled animal feed or a small bit of grain as well.

About a hundred yards directly west of the Burlington passenger depot was this building, on the Chicago & North Western tracks. Sanborn identifies it as a wool warehouse (there was a lot of sheep ranching in this area until the end of World War II when the bottom fell out. Most ranches switched to cattle at that point), belonging to the Douglas Warehouse Company. The original northern section (or maybe the southern section) of this structure is gone. Tracks were on the opposite side of this building from this view.

While I was running around taking pictures, I just happened to be in the right place when a BNSF freight rolled through town at 2:45 pm. I was shooting the Burlington freight house, and stepped out to catch the train on this video, which I posted on YouTube March 3rd. Trains don't even stop in Douglas anymore.

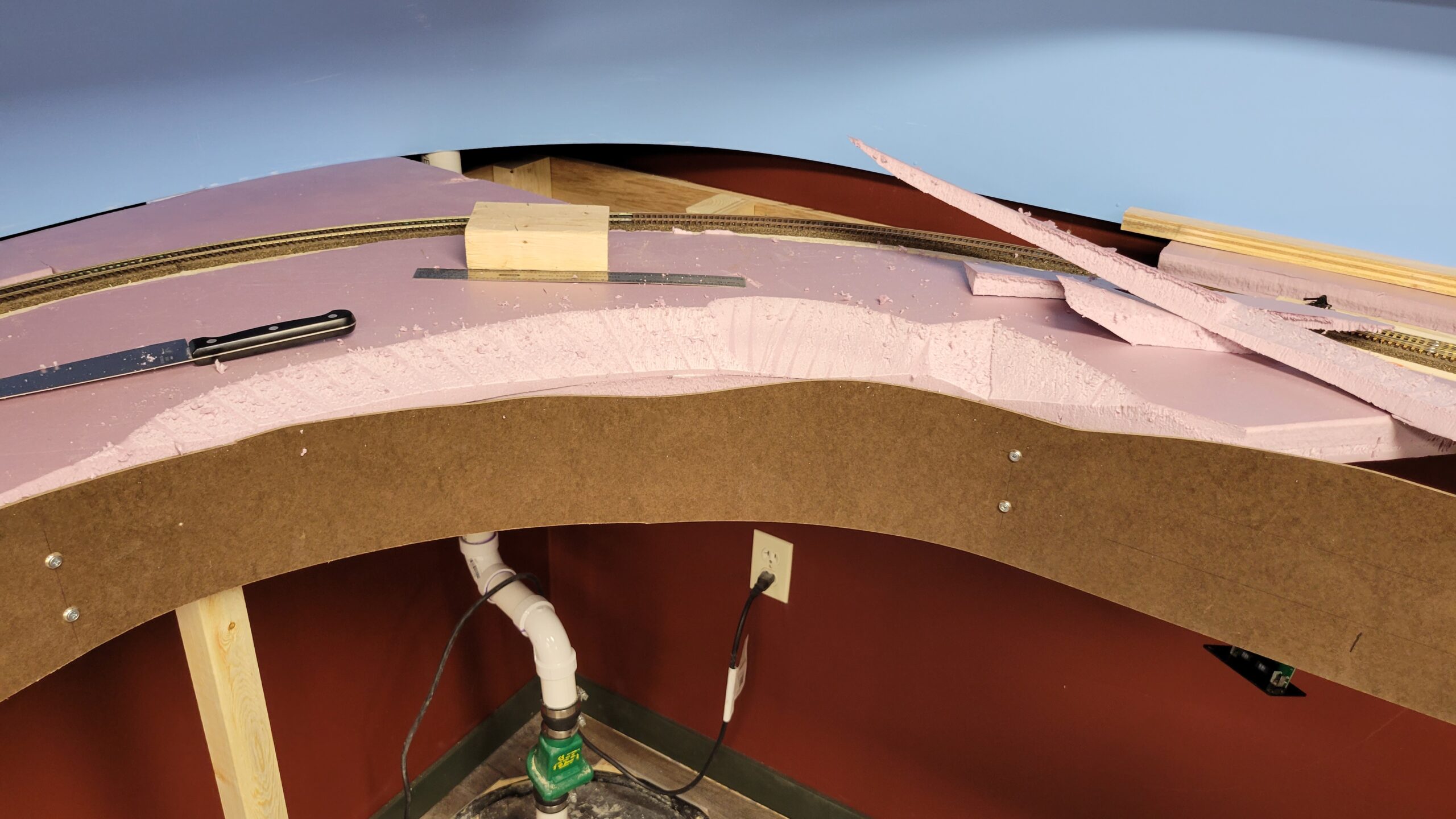

Over the next couple days I rearranged the shelves in the train room, built and installed the second and final piece of Douglas benchwork.

It's at a lower level because the Frannie cutoff will be descending under Douglas (towards the camera in this view), and will be on top of the far benchwork section. It will be low enough that it will dive under the higher section in the middle of this shot.

Yesterday I posted the March 3rd layout update video:

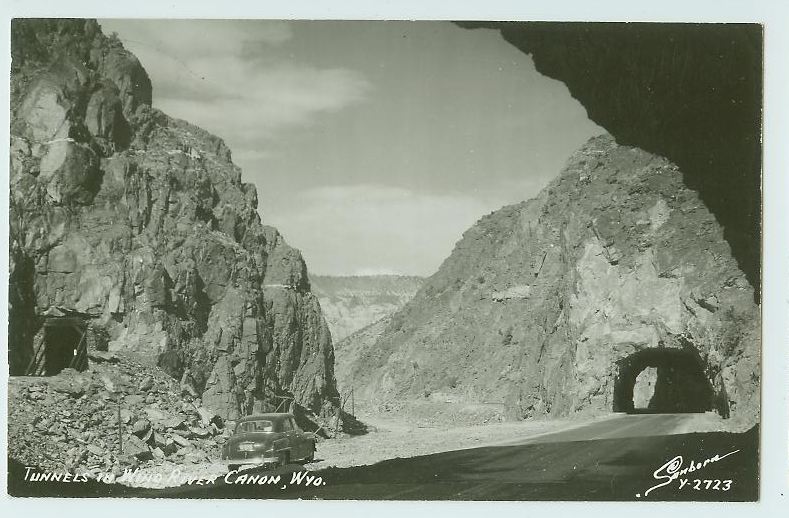

Yesterday afternoon I also held my inaugural operating session on the layout with Kurt, a friend who has periodic op sessions on his own layout. It was a big success! Even though ops are very limited at this stage of construction, he said he had a good time. We ran for about two hours. Here's Kurt running the Thermopolis local through the Wind River Canyon.

21 March 2022

I didn't realize it had been so long since I did an update. Lots been happening.

I did a little bit of work on Rocky Mountain Drilling, finally getting it planted IN the scenery rather than just sitting all cattywampus on top. Still a lot to do in the area, but it's a start. I need to get this done before extending the mainline east, which will make it harder to get to this area.

I've deferred locomotive maintenance for far too long, and with two of the three Mikados down for repair, it was past time to do something about it.

First I had to build a cradle for hold the locomotives upside down as I worked on them. I made this out of some felt I already had, and scraps of lumber left over from building benchwork.

I made a "How I did it" video about construction of the cradle and posted it on YouTube.

Since I needed a DCC connection at my workbench while working on the loos, I added the track buss wires from Casper through what will be the Douglas area, extending them all the way to the end of the benchwork I added just a few weeks ago. For now, my workbench sits at the end of that new benchwork.

Back to locos - I've had one Mikado that's been out of commission for some time because of a valve gear problem. I decided to try to address that while I was working on all the others. The valve stem (the rod that activates the valve that controls which side of the cylinder steam goes into when the loco is in motion), which sits above the piston rod, should move forward and back parallel to the piston rod. Here's a still from a video I made showing how far the valve stem can move up and down on this one loco:

That sort of vertical motion is not normal, and it causes the mechanism to completely jam up at times.

That sort of vertical motion is not normal, and it causes the mechanism to completely jam up at times.

Here's that video:

I contacted the manufacturer, Broadway Limited Imports, and they can't help. The loco is nearly 20 years old, and they don't have any parts remaining in stock to make repairs.

I thought I was down to two functional Mikados on the layout and was worried about how I would replace it. I might be able to repair the mechanism, but that would be a long and exacting process. Maybe someday...

Then an obvious solution came to mind. When I bought the three CB&Q-lettered Mikados BLI offered back in the early 2000's, my good friend Walt gave me a fourth one for my birthday. It's painted for the Cewntral Railroad of New Jersey, and I always planned on repainting and lettering it as a fourth Burlington Mike. I've never gotten around to doing that, so the loco has stayed in a storage box for almost it's entire life.

I dug if out and tested it. Runs like new (which really, it is)! I swapped the tender and the superstructure so that the Burlington loco has the new mechanism, and put the CRRNJ superstructure on the damaged chassis. I'm back to three Mikados on the layout.

One of these days I'll dig out the damaged unit and tear into it in an attempt to fix it.

While I was working on locos, I also dug out a very lightly used Athearn Genesis Pacific I picked up at a train show a couple years ago. When I tried to run it I found out why I had gotten such a good deal on it - the motor would spin but the unit would not move. Cracked gear!

North West Short Line has gears that fit, and I bought one right after I found the problem. Then I never installed it - that loco also went into a storage box until a few days ago. I partially disassembled the underframe, and you can clearly see the crack in the driving gear in this shot.

No solution other than to remove the geared driver and replace the gear. I disconnected the mechanism from the driver on both sides of the loco, carefully documenting each step with photos so I'd be able to reassemble it later. Here's the driver fully disconnected and ready to be lifted out.

I have no way to pull the driver off the axle to replace the gear, so I ordered a Puller from North West Short Line (those guys are real lifesavers at times!) on Friday. When it arrives I'll be able to pull the driver and gear and complete repairs on the loco. Hopefully I'll have it in running condition soon.

I have no way to pull the driver off the axle to replace the gear, so I ordered a Puller from North West Short Line (those guys are real lifesavers at times!) on Friday. When it arrives I'll be able to pull the driver and gear and complete repairs on the loco. Hopefully I'll have it in running condition soon.

Friday I dug all the L-Girder sections of benchwork out of the storeroom and took them apart. I'd saved them from version 4 of the layout in New Jersey, planning on using them on the new layout in Casper.

As it turns out the only place I was able to use them is under Casper yard (because the benchwork with the L-Girders is far too deep for my current track plan because it has hidden track under almost every section). All the rest of the sections were stuffed into a storeroom until now. Here's all that benchwork disassembled. Takes up a lot less space! I'll be able to reuse nearly all of it except most of the L-Girders.

27 March 2022

An update on the Athearn Pacific:

Kurt, who was here for the inaugural operating session on the 3rd, had a NWSL Puller, so I borrowed his while waiting for mine to arrive.

On the afternoon of the 21st I pulled the wheel, installed the new gear with only a little difficulty, and reinstalled the wheel.

Confident in my repair work, I reassembled the locomotive and put it on the track to test it. I advanced the throttle, and... the motor spun but the loco didn't move!

%#$&!

Clearly there was another problem. I disassembled the loco again, this time removing the boiler and pulling the weights apart to expose the drive mechanism above the gears. I found this.

There's a flexible coupling between the flywheel and the worm. On the worm shaft the press-fit coupling end (which is apparently made of the same material as the cracked gear), is also cracked. The flywheel was spinning but the coupling end no longer grips the worm shaft, so it just spins around the shaft.

There's a flexible coupling between the flywheel and the worm. On the worm shaft the press-fit coupling end (which is apparently made of the same material as the cracked gear), is also cracked. The flywheel was spinning but the coupling end no longer grips the worm shaft, so it just spins around the shaft.

Unfortunately, NWSL doesn't make a replacement for this part. I spent the better part of a nearly sleepless night working out a solution. What I came up with -

The shaft is 2 mm in diameter. I ordered some flexible plastic (like neoprene) tubing with a 1.5 mm inside diameter from Amazon. My idea is to remove the coupling altogether and replace it with the tubing. I've seen these kinds of flexible couplings before and they work pretty well. I hope the tube will grip the shafts tightly enough to transmit the power to the work and the drivers. If it slips, I'll use some vice grips to scar up the shafts so the tubing has a better grip.

If that doesn't work I'll probably chuck the whole thing in the trash.

Tubing arrives tomorrow.

Since I'm at a standstill on the Pacific, I changed direction and put together the backdrop image for Powder River and Shobon. Kurt provided the main photo, and I combined it with the end of my Casper backdrop photo so I'll have a seamless backdrop extension out of Casper. I had it printed and it's waiting for final cutting and installation.

I was about to start installing the new backdrop when I realized I still needed to paint the track. So off I went to do that.

My least favorite part of the hobby is replacing ties missing at rail joints. I had a lot of those to do, since I've been mostly laying track the past few months. Everything outside of Casper, including Riverton, Powder River, Shobon, the entire Wind River Canyon and Thermopolis was missing ties.

So I got started. Over a few days I prepped and installed replacement ties for everything up to Thermopolis. I'll do that town later.

I trimmed up and installed what seemed like a thousand ties but was really only 50 or 60. I installed them and painted the track.

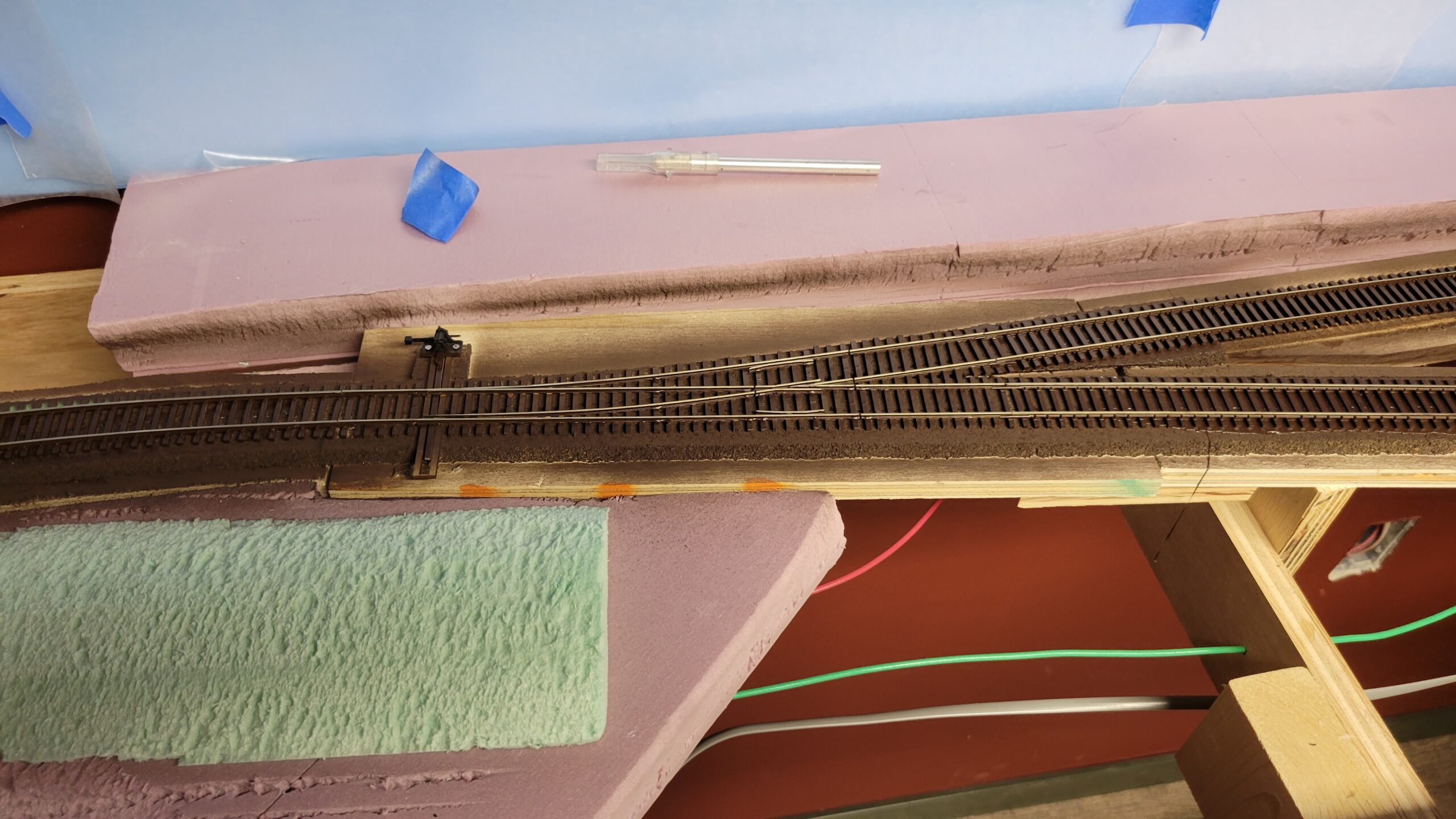

Here's three photos showing the work at the Shobon switch.

30 March 2022

The tubing I ordered arrived on the 28th. I removed the flywheel end of the coupling. That end, recessed into the flywheel, had the same sort of plastic coupling end pressed onto the flywheel shaft. On that end the coupling wasn't just split - it was broken into two pieces! No wonder the thing wouldn't move! I fished out the pieces with a pair of tweezers.

I cut a short piece of tubing to fit on the shafts. Here's what it looked like:

I pressed the tubing onto the flywheel shaft, then cleaned up the worm shaft (it was covered with oil). I pressed the worm shaft onto the tubing and set about reassembling the running gear. The motor and worm are housed in a two-piece weight. Only the idler gears stick out underneath, to engage the axle gear on the drivers.

Once I had the weights bolted together I worked that assembly back into position on the chassis. That was it for the loco for the day.

The next morning (the 29th) I attached the motor assembly to the chassis. This took about an hour because the motor wires have to be positioned just so or the assemblies don't fit together right. It took me half a dozen tries to get the wire routing figured out, but once I had the mechanism fully reassembled I tested it. It seemed to run just fine. I ran it in forward and reverse (upside down in the cradle) and the motor actually turned the wheels!

I spent a couple hours reassembling the rest of the unit. Putting the boiler back on was a bit tricky, but once I figured out what I was doing it went right together. Before I reinstalled the cab I took the loco over to the layout and tested it on the track. Success! The mechanism is very stiff, but it may loosen up as I run the loco. Evidence suggests the loco was never run at all until I got it. A roughly 12 year old mechanism that was never run at all and sat in a box all that time certainly might be stiff!

I finished reassembling the loco and attached the tender. I had to add a coupler to the tender, because whoever owned the loco before me never attached it. Handrails, whistle, tender coupler and all other parts which Athearn supplied but left to the purchaser to install were in the box but had never been installed. I added a coupler but have yet to add all the loco details.

Here it is sitting on the layout. You can see the holes in the sides of the boiler where the handrail stanchions go.

I ran the loco back and forth a bit, then attached a short string of stock cars.

I made a short video of the loco pulling the cars.

If you listen closely, you can hear a lot of gear noise, especially in reverse. There isn't provision built in for adjusting the gear engagement, but I may loosen the drive mechanism and try to reposition it slightly, using the slop in the clearance holes for the mounting screws. If I do, I'll probably also replace the idler gears, which I didn't do first time around. I have the replacements from NWSL.

All in all I'd call this exercise a qualified success. The loco runs and pulls freight cars, but it's very stiff and noisy.

The tender also tends to derail at the front truck because of the screwball way the decoder is installed. There's a very stiff wiring harness that runs from the loco back through a slot in the tender. The harness is stiff enough that it can lift the front truck of the tender partially off the rails.

This loco was sold by Athearn new for around $140. I got this one at a train show for $40, and I spent another $25 or so the replacement gears. So I've got about $65 into it, plus 25-35 hours.

These units, along with the Mikado Athearn had out at the same time, are notorious for the cracked gears, and there have been complaints about the wiring harness issue as well. Unless I can reduce the gear noise and loosen up the mechanism, plus solve the wiring harness issue, I'll probably sell the loco at a train show at some point. Though getting it to run halfway decently is a satisfying victory, at this point it doesn't run well enough to put into regular service on my layout (I'm a real bug about smoothly running equipment), plus the history of the entire production run may make it too "iffy" to keep around. We'll see.