Casper Construction Progress Part 3 – 2024 – July through September

3 July 2024

On the 19th, with the staging yard basically built and waiting on components for the control panel rebuild, I turned my attention to the BLI Blueline loco that had the bad sound board.

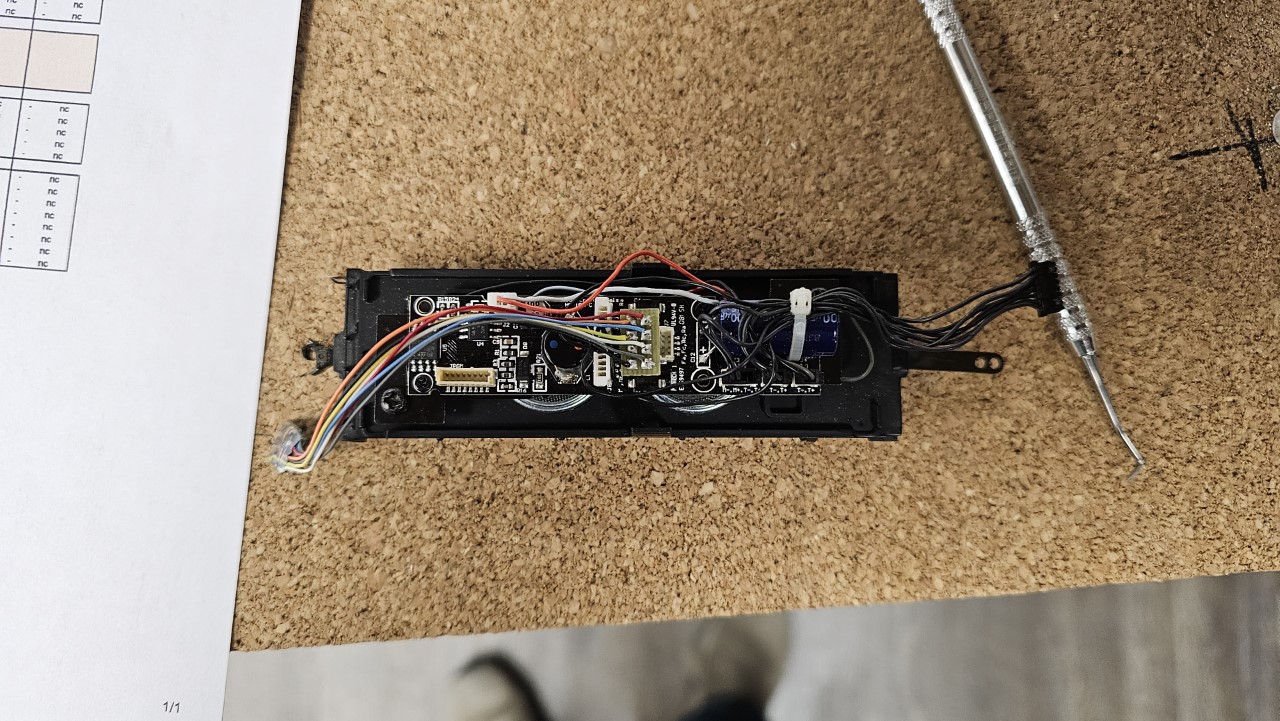

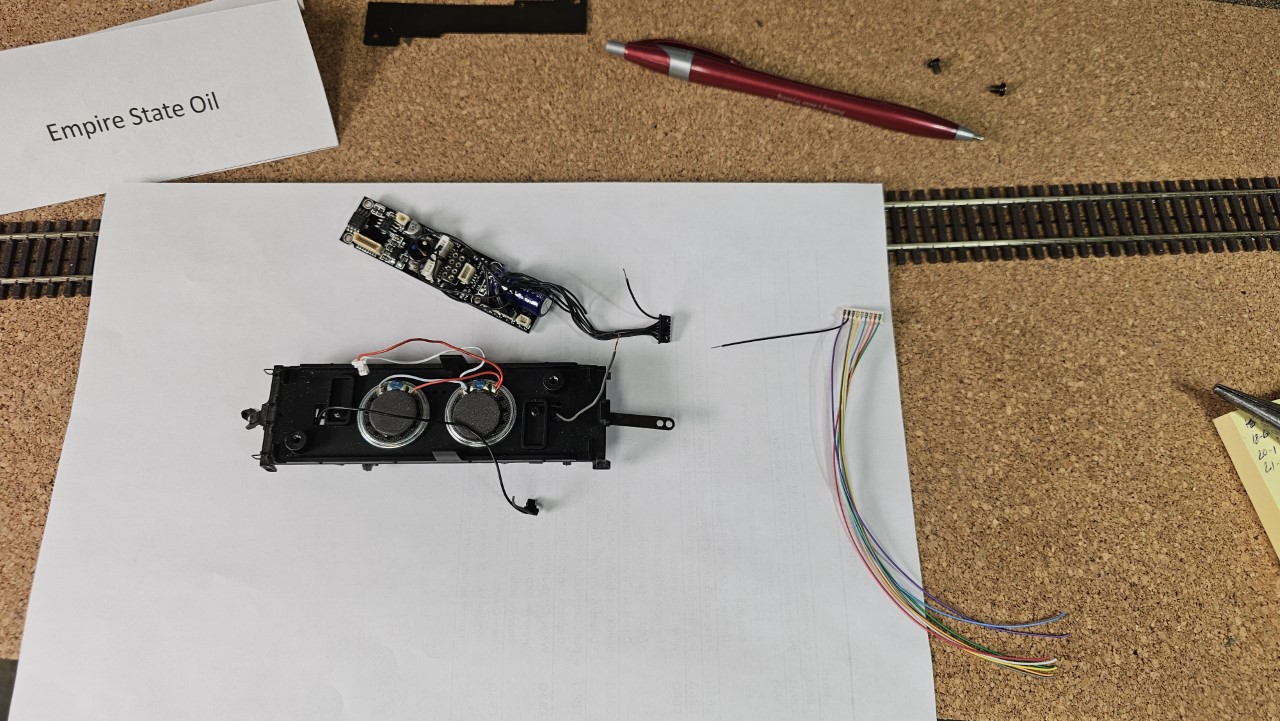

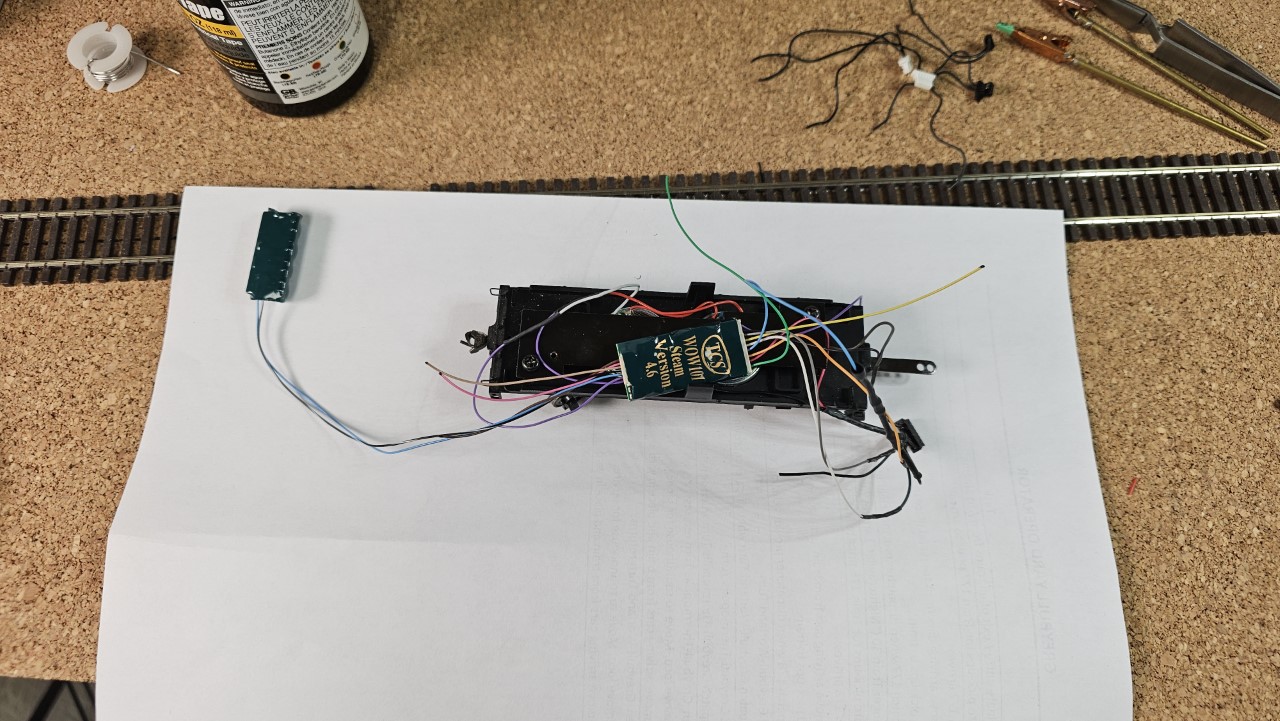

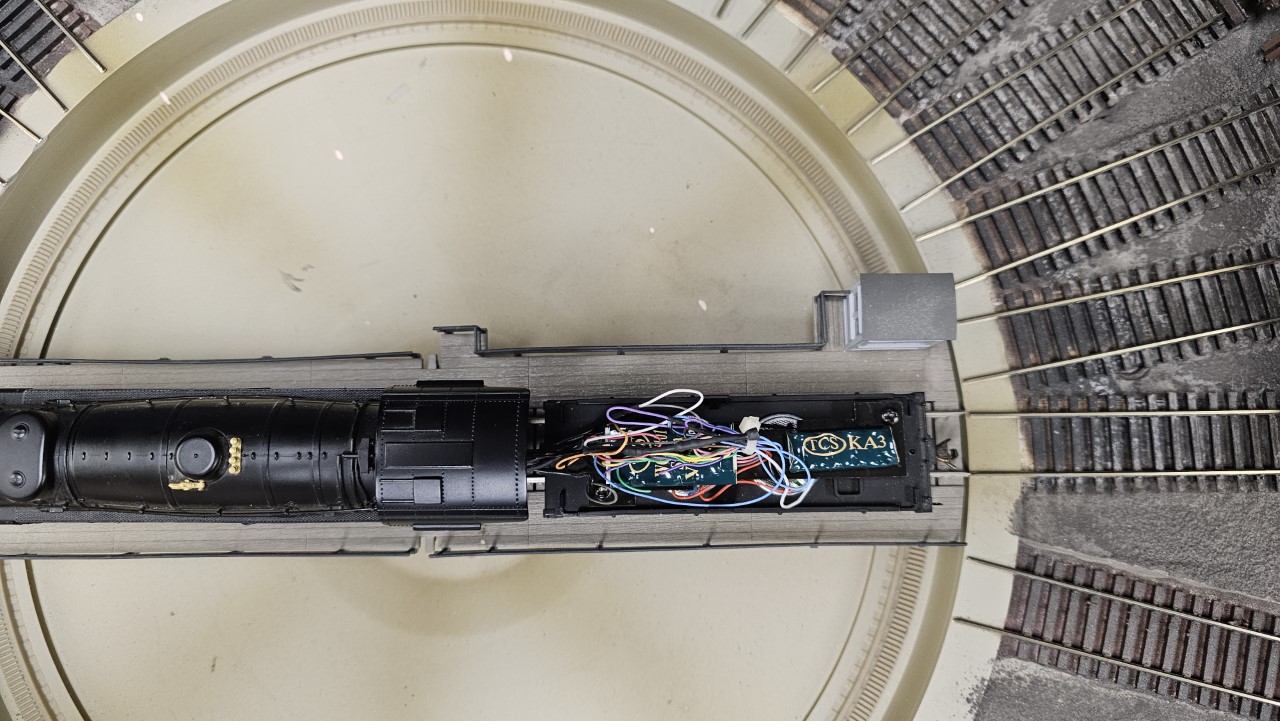

Here's the original decoders in the tender. The motor decoder is the small piece with all the wires that's hanging behind the tender.

I spent a couple more days building train manifests in JMRI and making sure everything was in place on the layout. This time around I blocked both the incoming trains and the yards themselves, so the operators wouldn't have to hunt and pick cars one or two at a time. Then the big day came! For this operating session, Kurt, foreground, is handling the Casper local switcher while Bill is acting as Casper yardmaster. They made a pretty effective team! Casper wasn't the bottleneck it had been during the March session.

A few days ago I put together a short video with clips from the operating session.

Today I posted my latest layout update video:

25 July 2024

On July 23rd I posted a late 4th birthday video for the layout:

11 August 2024

On August 3rd I uploaded my latest layout update video to YouTube.

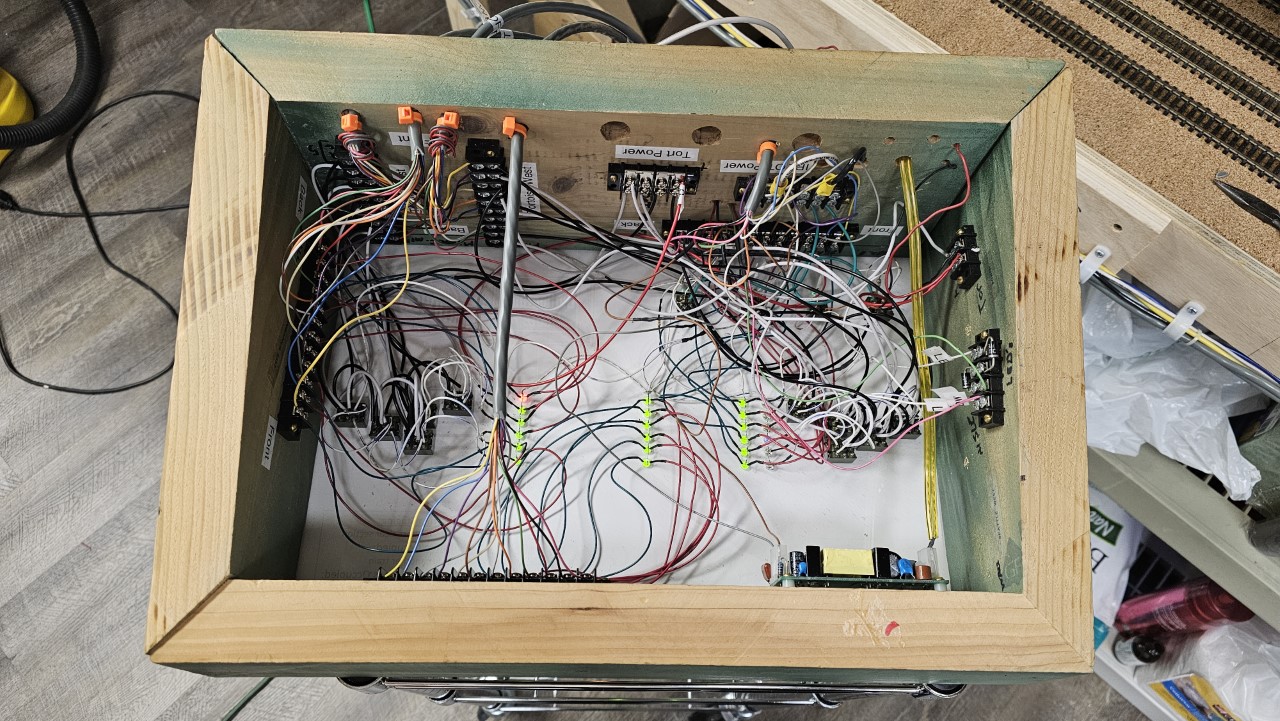

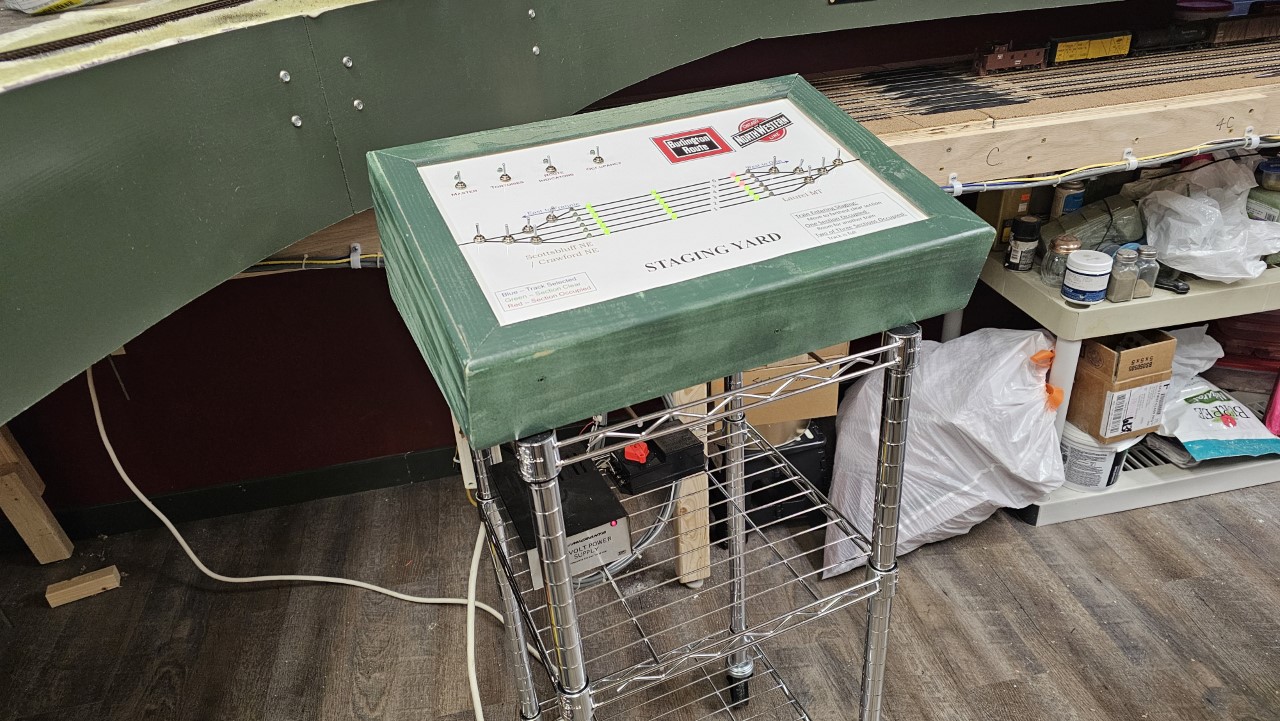

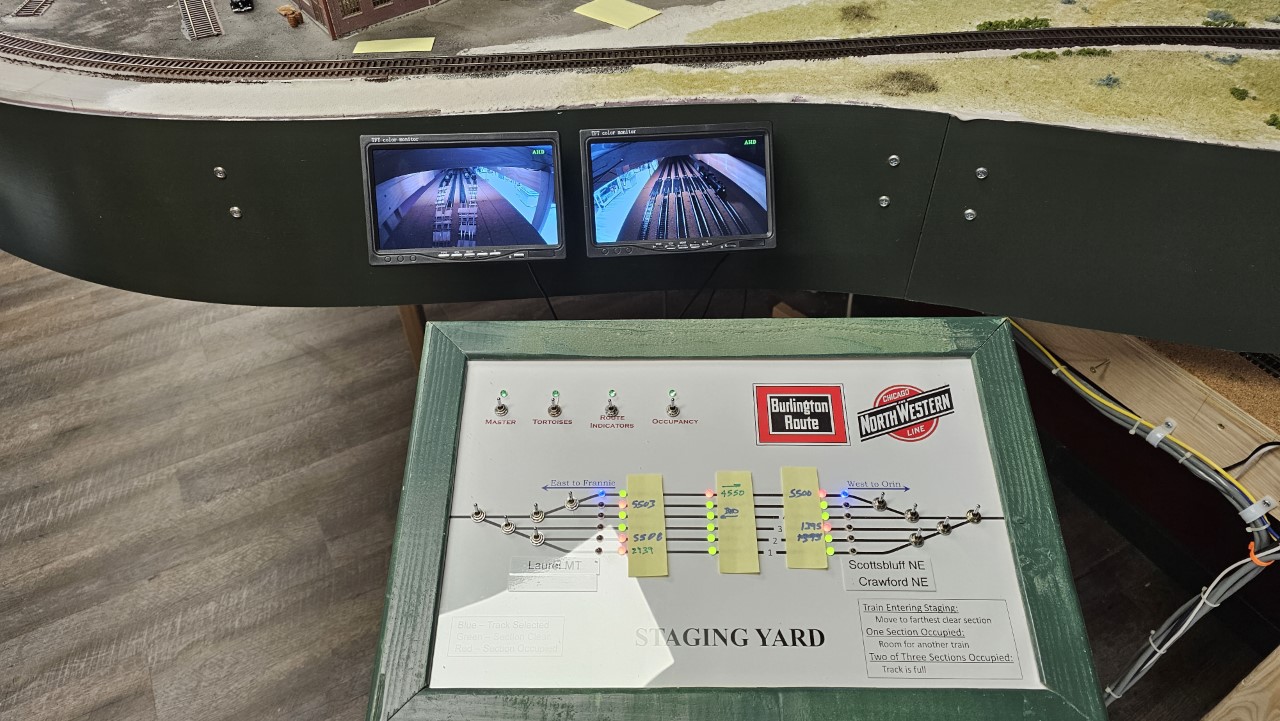

Two trains sitting at the west end of the yard awaiting their turns to appear on the layout.

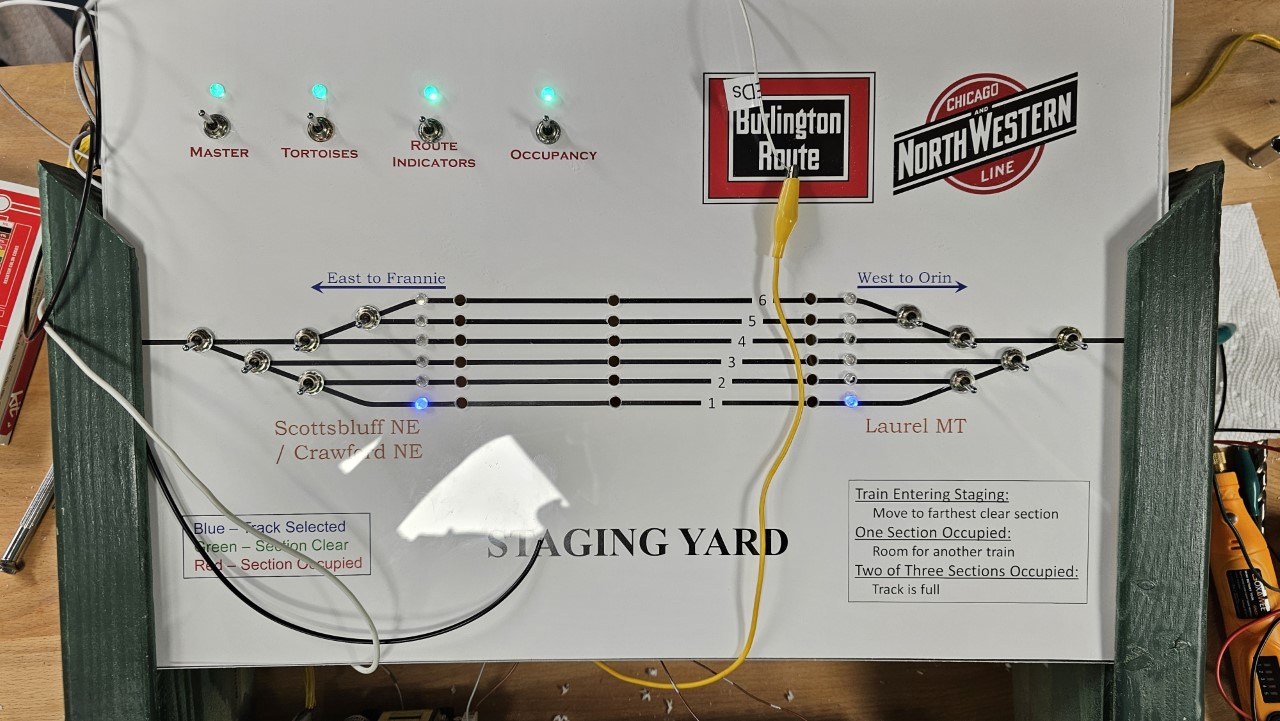

Testing isn't complete yet - it'll take a couple weeks of off-and-on work to complete that. I'm also planning on adding a camera or two to the yard - even with the occupancy detectors a camera pointed at the west yard throat will be a big help to the staging yard operator.

Testing isn't complete yet - it'll take a couple weeks of off-and-on work to complete that. I'm also planning on adding a camera or two to the yard - even with the occupancy detectors a camera pointed at the west yard throat will be a big help to the staging yard operator.

I'm also going to do some tweaks to the panel stand.

23 August 2024

On the 13th of August Dave came down from Basin. We spent the morning visiting Chuck Eckerson, a retired employee of the Burlington here in Casper, then in the afternoon we installed the end section of backdrop on the Worland / Basin Peninsula.

Here Dave is inside the access hole in the benchwork preparing to mount the backdrop.

Over the next few days I worked on re-lettering Milwaukee Mikado 330 and preparing some tank cars for the layout, including the Tangent cars I bought at the Cheyenne train show on the 30th of June. I was rather dismayed at the condition of those new Tangent cars when I removed them from the box - three of the four had damage or were missing parts! Not what I expected for over $45 per car.

I contacted Tangent asking for replacement parts, and they said they would send me a whole new car I could cannibalize for the parts I needed. That was great, but I would have preferred cars that were not flawed in some way to begin with.

Here's the damage on one of the cars. When I took it out of the box a stirrup step looked like this:

I managed to repair it, but in preparing the cars for the layout (Kadee sprung trucks, which forced me to change the couplers to overset shank ones for the coupler height to be anywhere near correct) parts kept falling off! Coupler pockets were partially glued in place, though they weren't supposed to be. Rushed assembly, it appears.

I managed to repair it, but in preparing the cars for the layout (Kadee sprung trucks, which forced me to change the couplers to overset shank ones for the coupler height to be anywhere near correct) parts kept falling off! Coupler pockets were partially glued in place, though they weren't supposed to be. Rushed assembly, it appears.

These cars look great and are loaded with detail, but I'm not at all confident they'll hold up under regular use. I think the Proto 2000 kits are the best compromise between detail and durability. I don't buy many RTR cars, and this experience has strengthened my decision to stay with kits.

I'll get the weathering complete on two or three of the Tangent cars today.

Over the last week I've also spent quite a bit of time testing the staging yard. Everything seems to be working well.

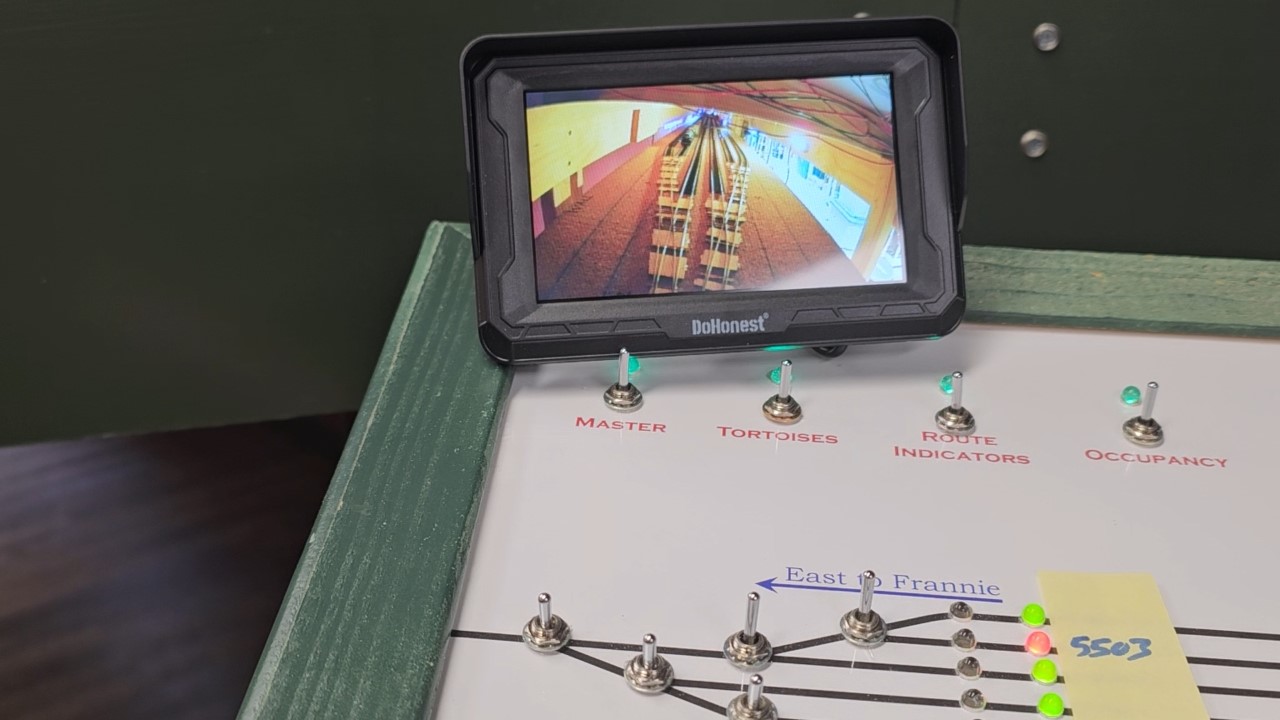

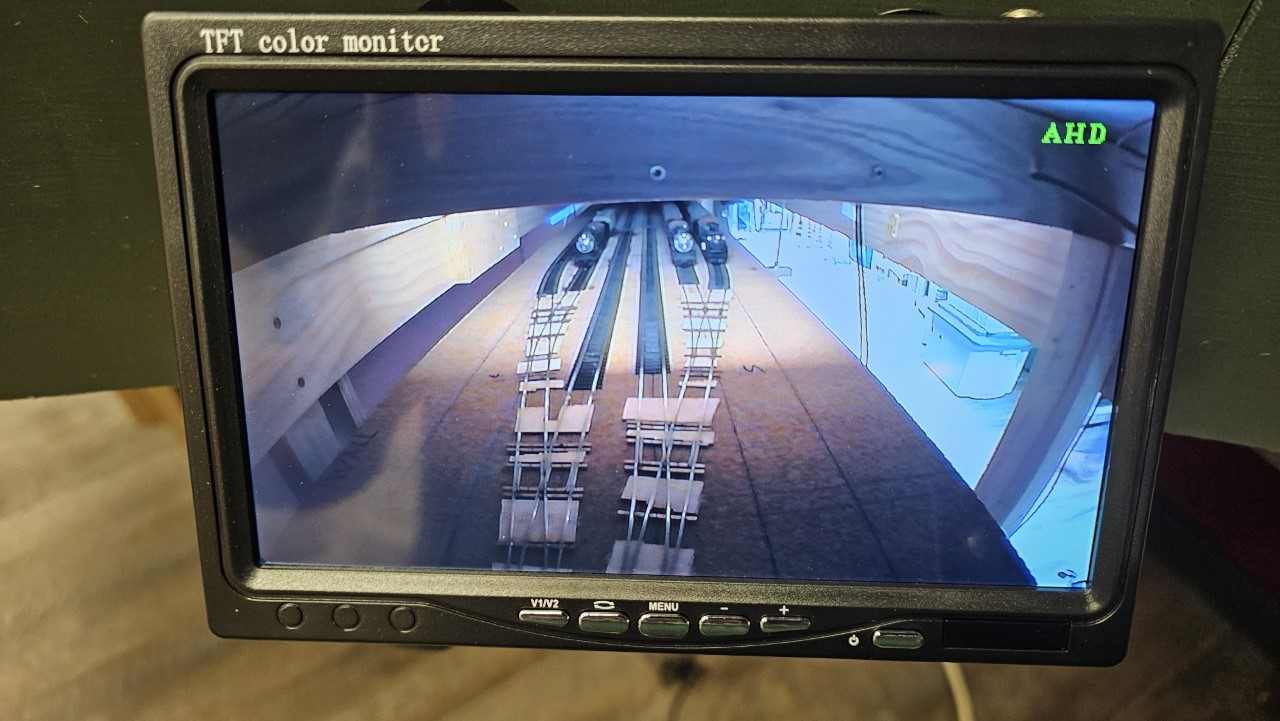

I bought a backup camera kit off Amazon and installed it at the west yard throat. Here the monitor is just sitting on the control panel while I test it out.

It works really well, but the 4.3" monitor is too small. I bought a system with a 7" monitor and tried it out. The monitor size is a great improvement, but I returned that system because the image quality wasn't very good - dark and light waves flowed down the screen. I have a new system arriving today, so maybe that will work out better.

It works really well, but the 4.3" monitor is too small. I bought a system with a 7" monitor and tried it out. The monitor size is a great improvement, but I returned that system because the image quality wasn't very good - dark and light waves flowed down the screen. I have a new system arriving today, so maybe that will work out better.

14 September 2024

After working with the 4.3" monitor for staging for a short period of time, it became obvious that the monitor was just too small to use. I ordered a different system that had a 7" monitor, but the image on that one was terrible. I returned it and ordered from yet another company.

That one tested out okay. The larger screen works much better, so I installed it on the layout fascia.

Here's the final arrangement of the control station for the staging yard. The monitor to the left looks at the west end yard throat, the one on the left side of the control panel. The other monitor looks at the center of the yard. The east yard throat is visible to the staging yard operator, so there's no need for a camera there.

On September 3rd I posted my latest layout update video.

With the turntable installed, I decided to work on the fascia leading from the Wind River Canyon into Thermopolis. First I had to prep the area for the new fascia panel, adding a splice at the adjacent panel and a 2X4 to guide the fascia around the new turntable. The untrimmed fascia sheet is sitting on the floor at the bottom of this picture.