Modeling – The Present – Version 5, The Casper Layout

This page shows current construction on the layout. The most recent entry is at the top, and they get older as you scroll down.

25 December 2025

MERRY CHRISTMAS!

Today I posted my 4th annual Christmas Layout Tour to YouTube.

7 December 2025

On November 3rd I posted my latest video update to YouTube:

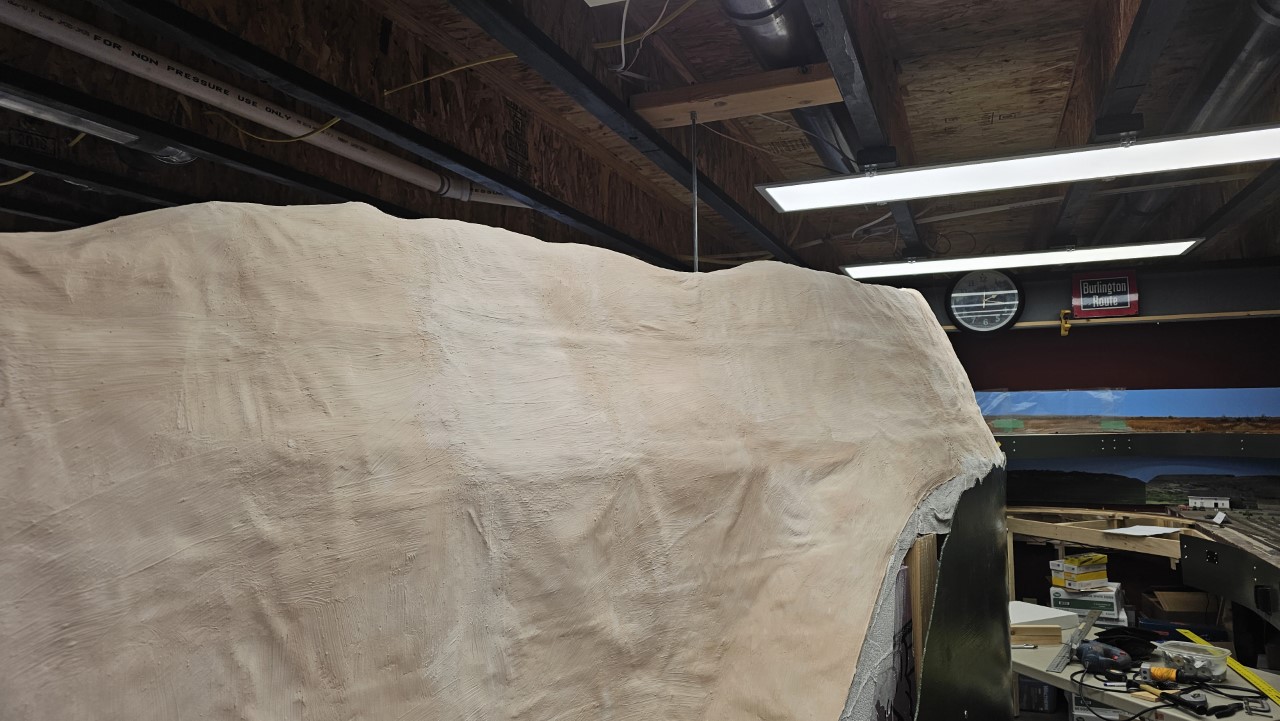

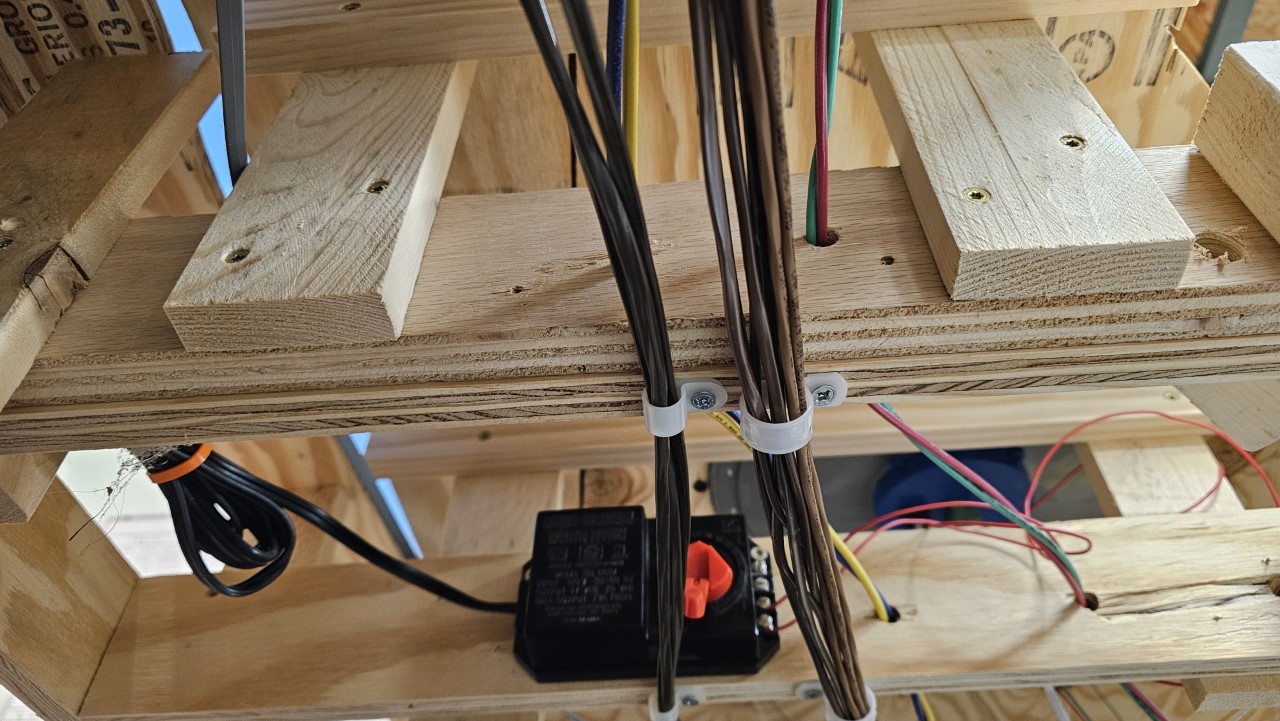

I decided to support the end of the Canyon on the Cody side of the peninsula with a threaded rod from the ceiling above. I added a 2X4 under the upper deck benchwork and a 2X6 hangar to the ceiling joists, then added the threaded rod. In this photo the rod bottom has yet to be trimmed.

On December 3rd I posted layout update video #73 to YouTube.

I planned on running one of the Scale Trains SD7's with the Proto SD7, and the other one with the Proto SD9. That way I'd have two loco sets, each with one sound engine.

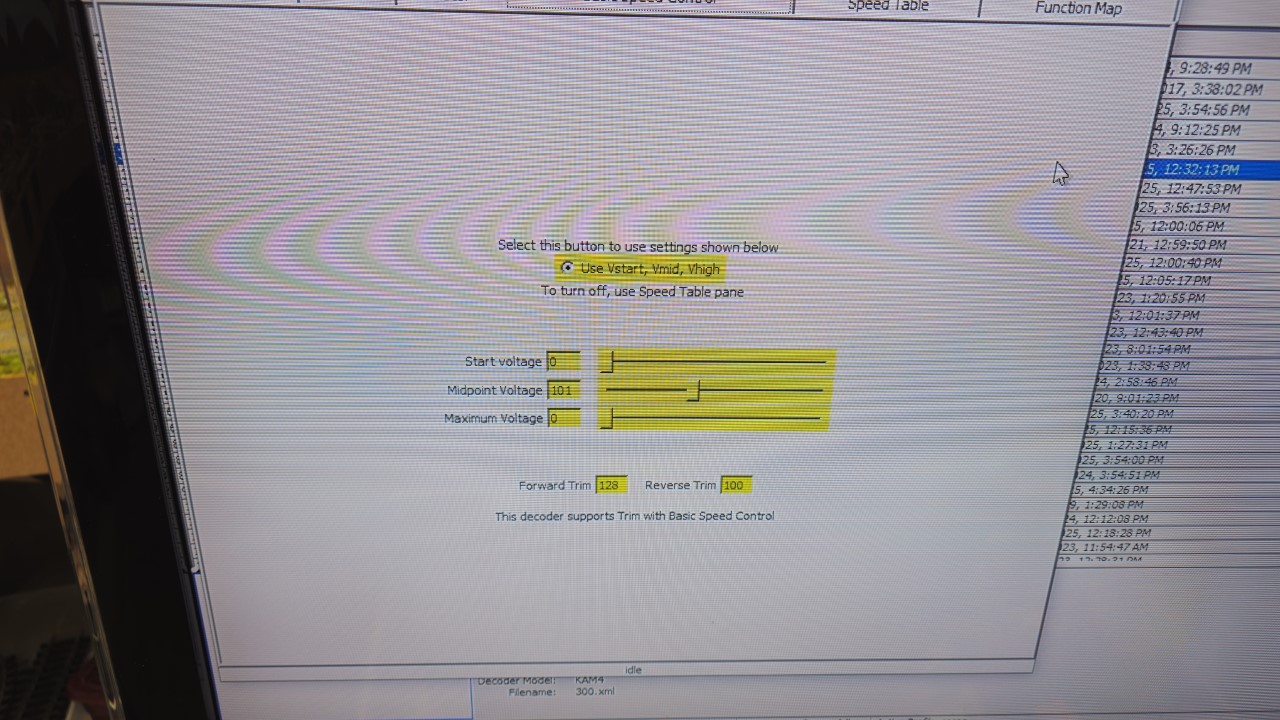

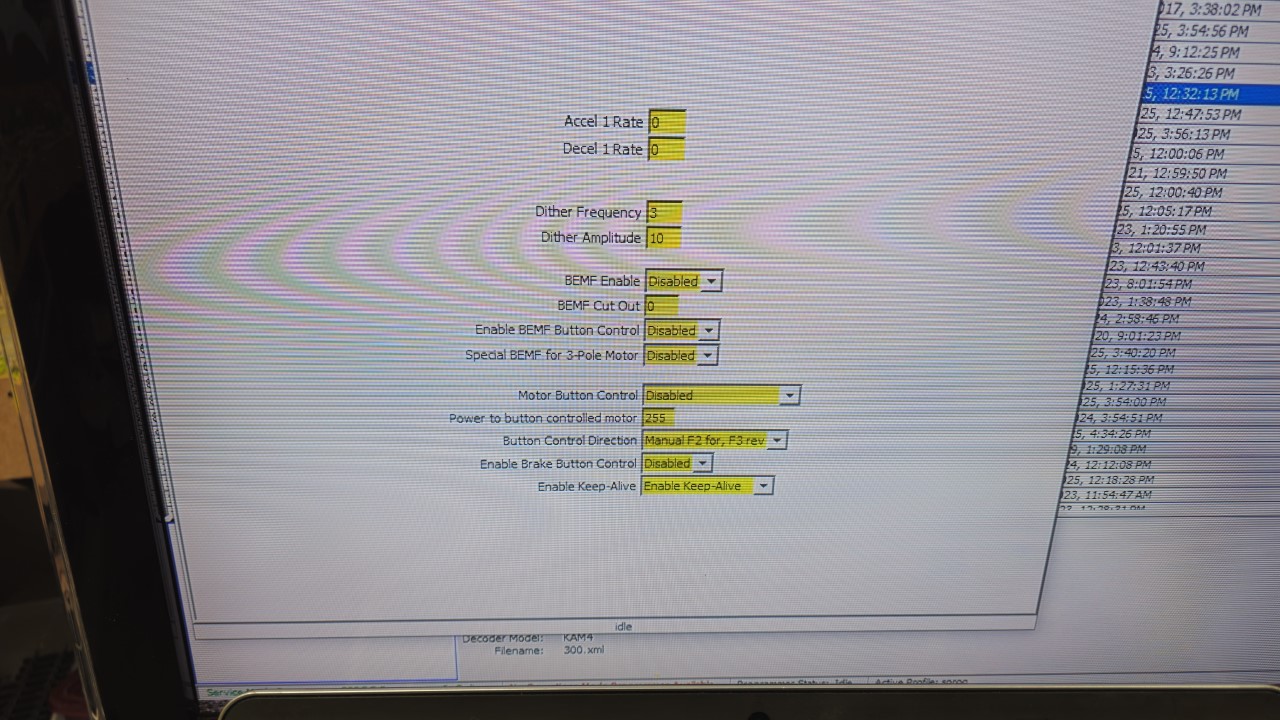

It took quite a bit of time to get the Scale Trains and Proto locos properly speed matched. With advice I got on the Model Railroad Hobbyist forum, I set momentum to zero and deactivated Back EMF for all locos. I switched the Proto units from using the speed table to just using Vmin, max and mid. I had to adjust Vmid from the default value to get the midrange speeds to match the Scale Trains units. Here are screenshots of the Proto settings I used:

25 October 2025

On October 3rd I posted the monthly layout update video:

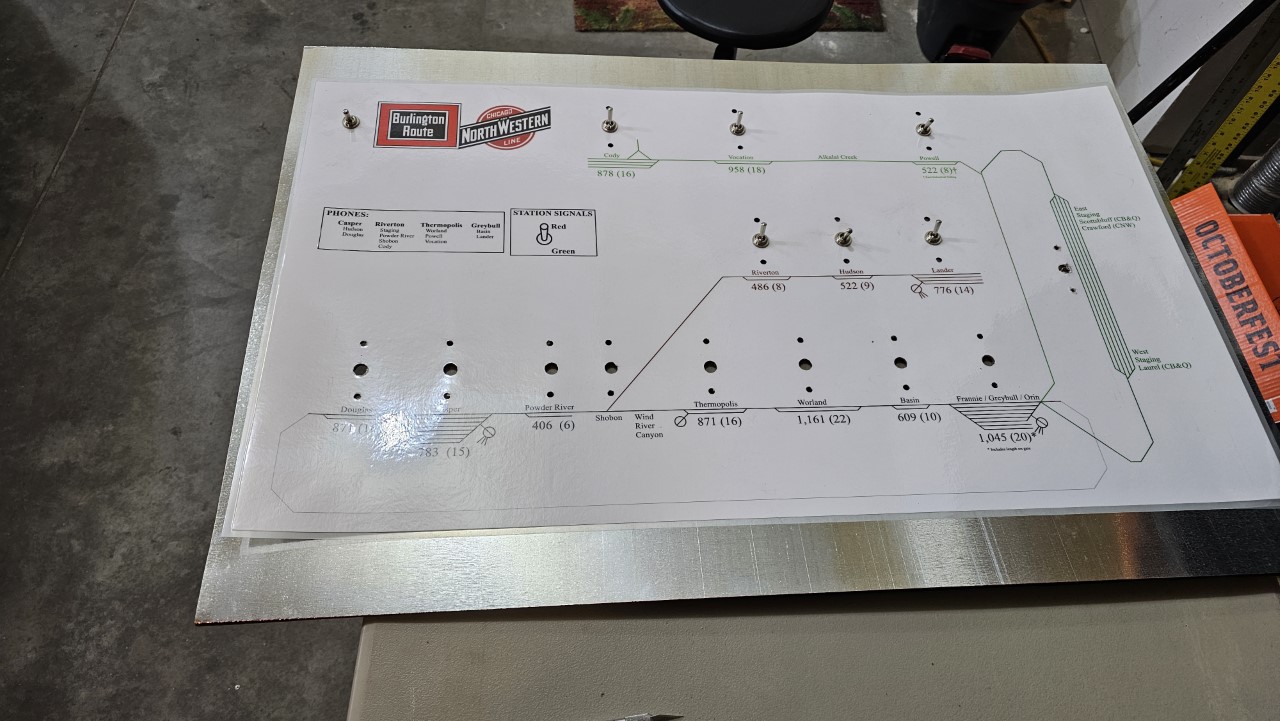

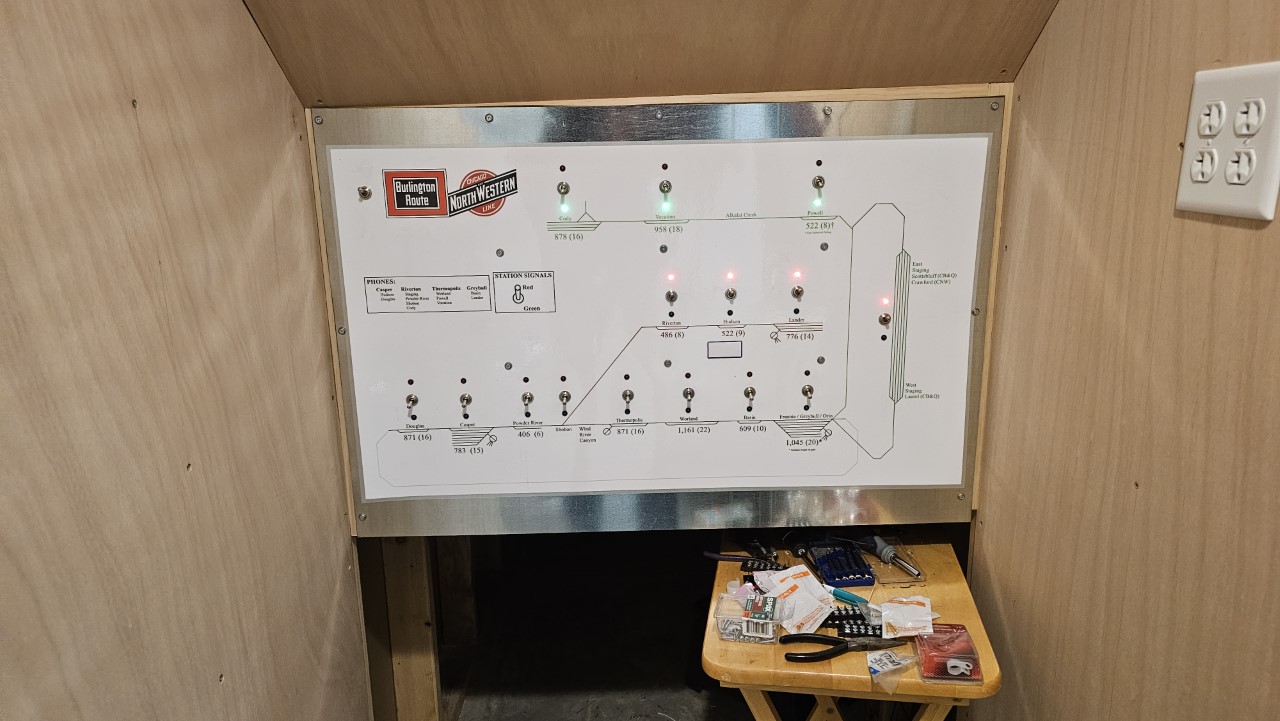

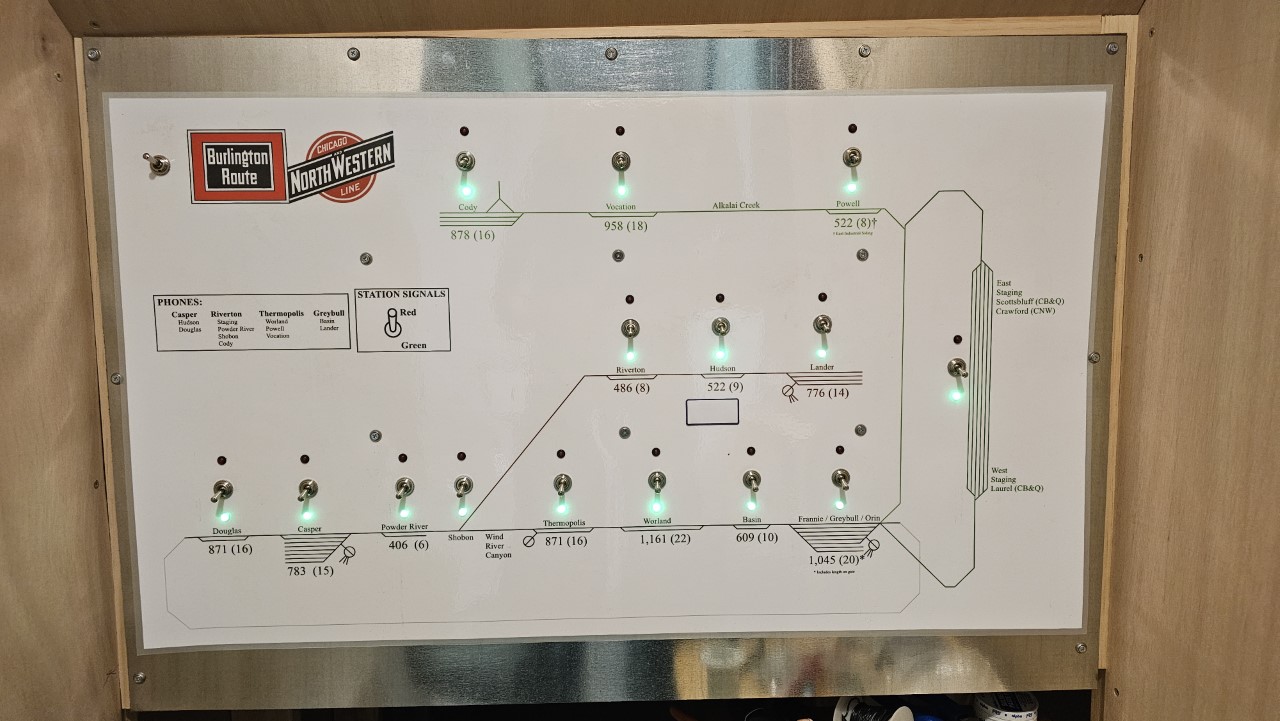

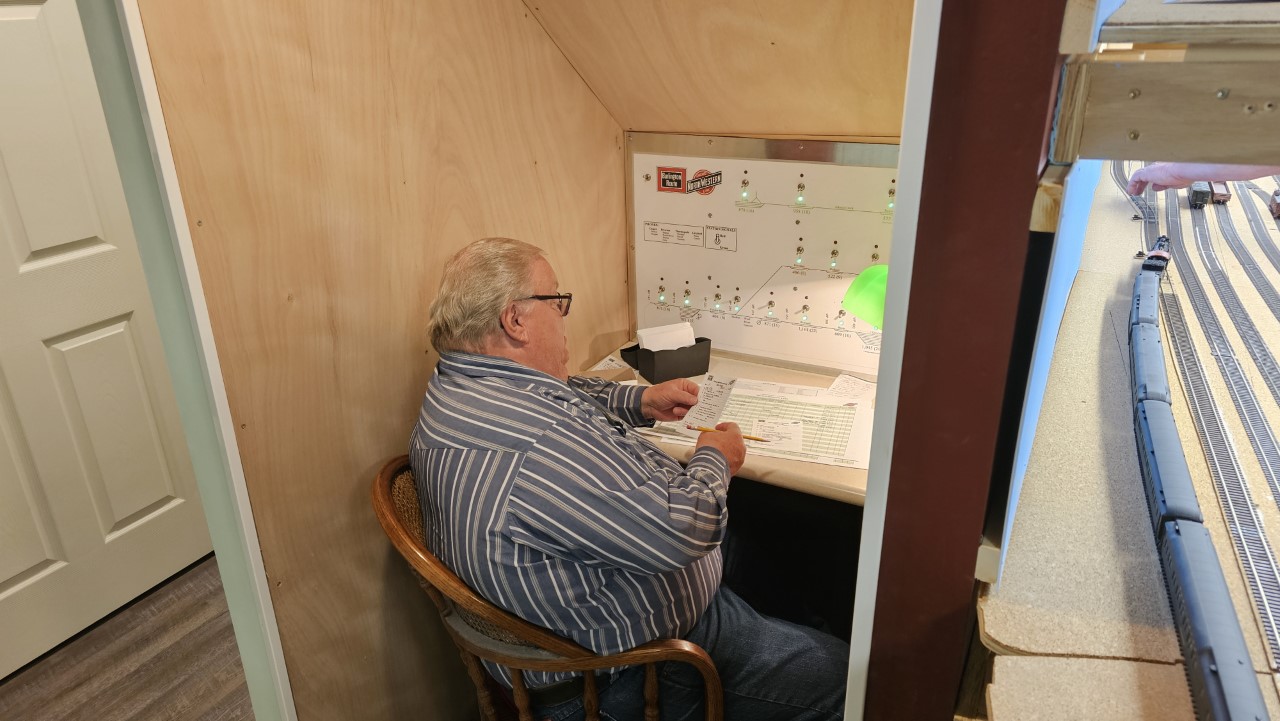

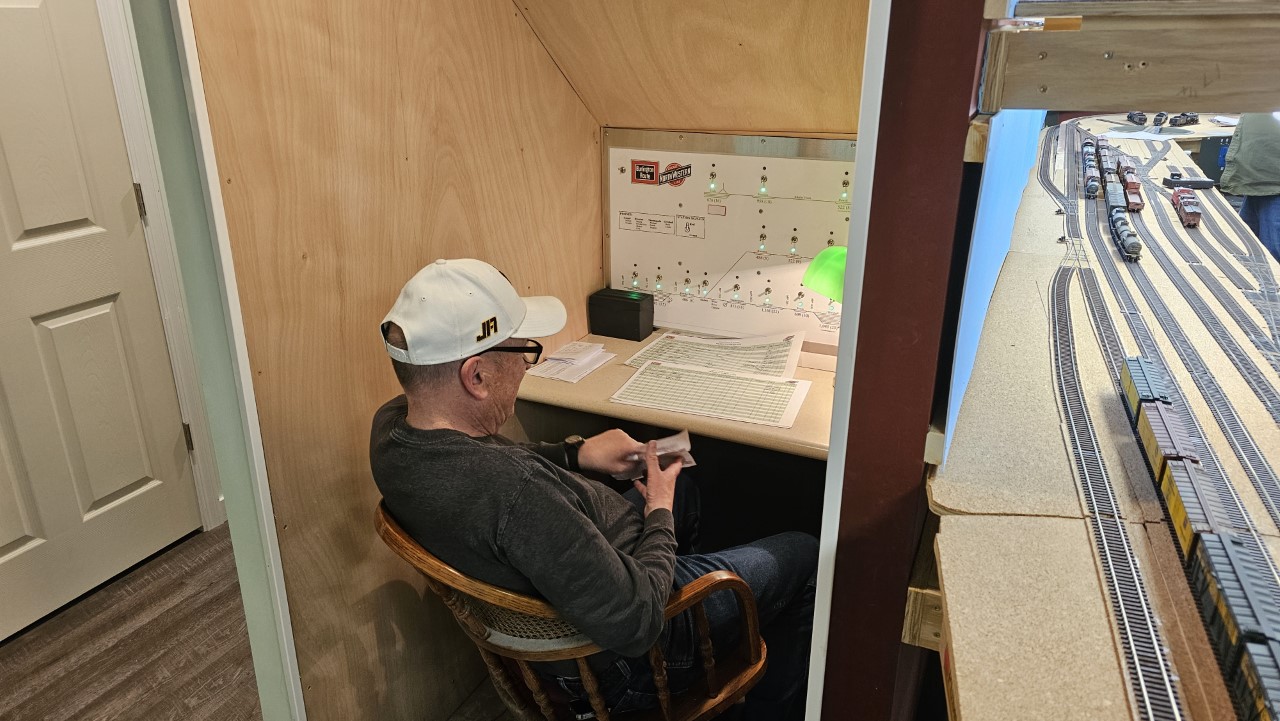

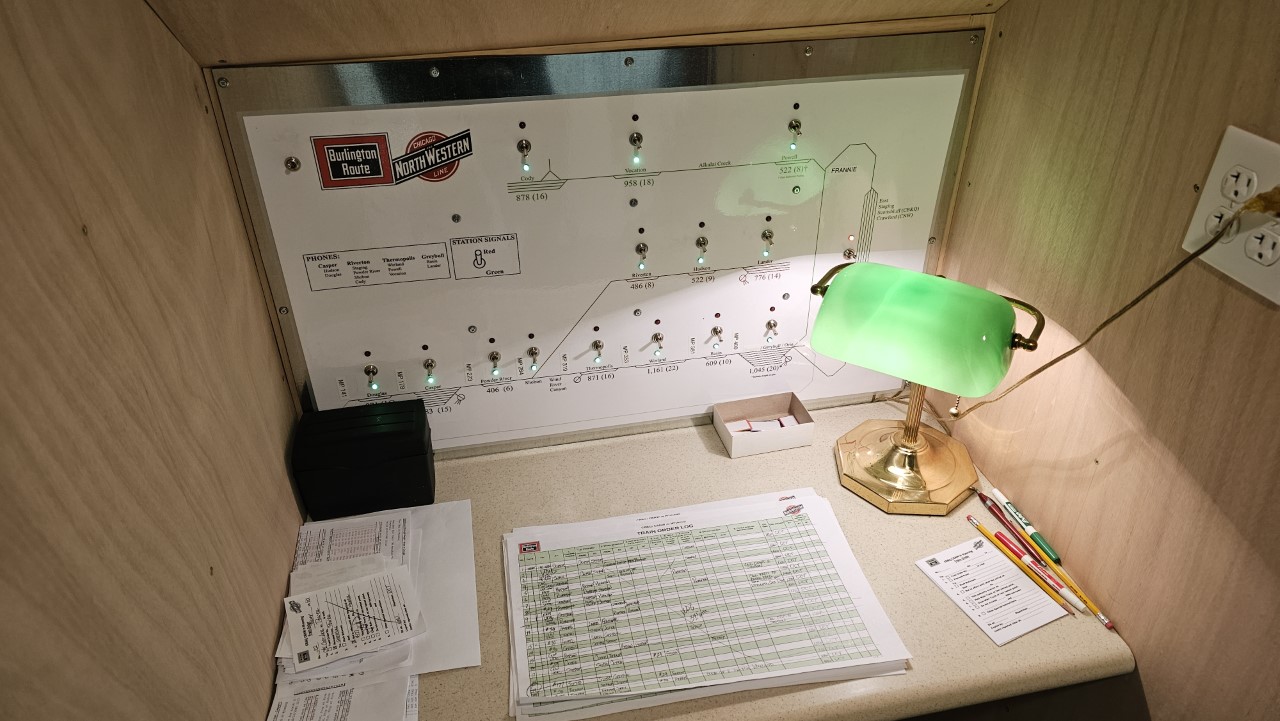

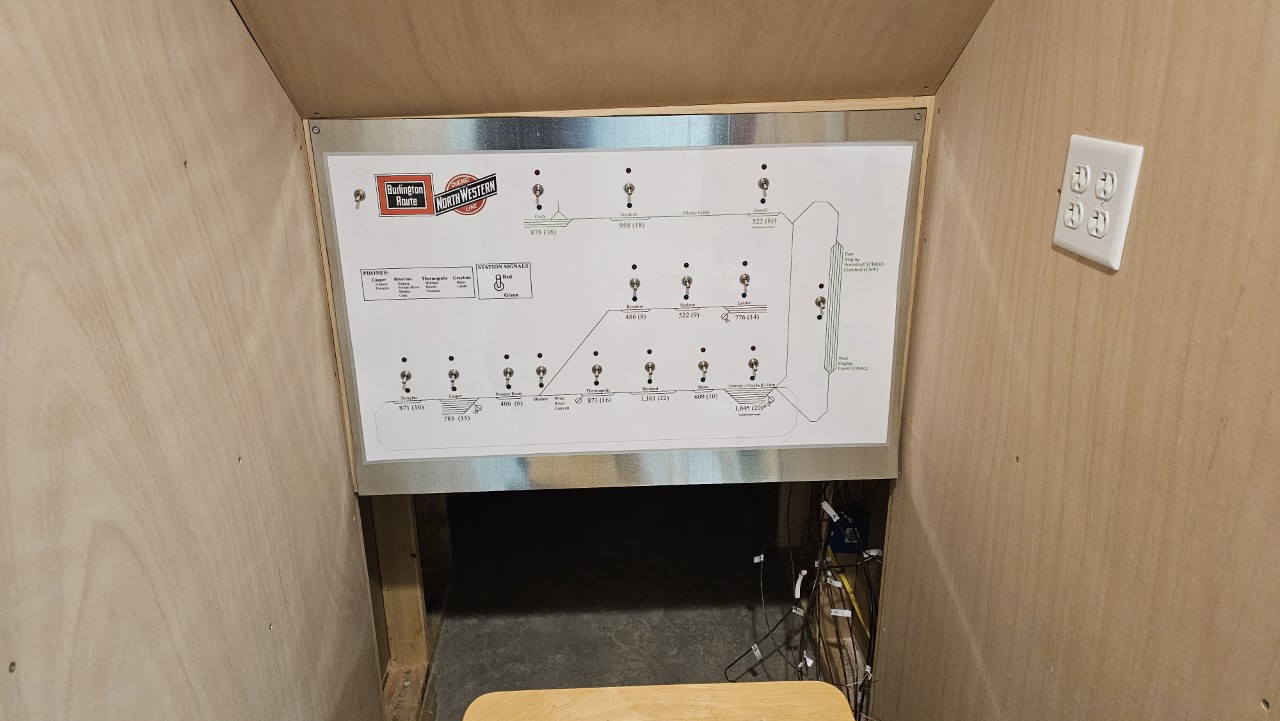

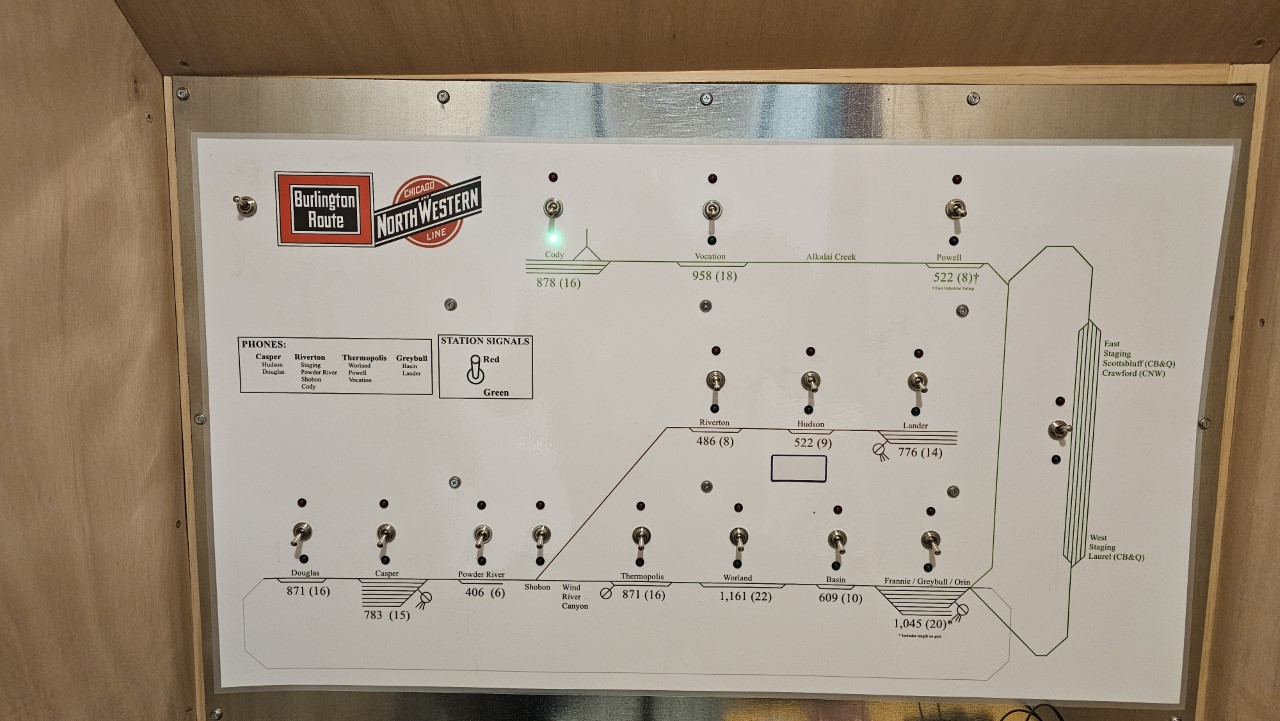

Once all the switches were installed I moved the panel into the dispatcher's office and mounted it with a couple of screws at the top corners. The panel is level; it looks crooked because the two stair walls are not exactly even, meaning the panel is very slightly canted on the vertical axis relative to the stairs.

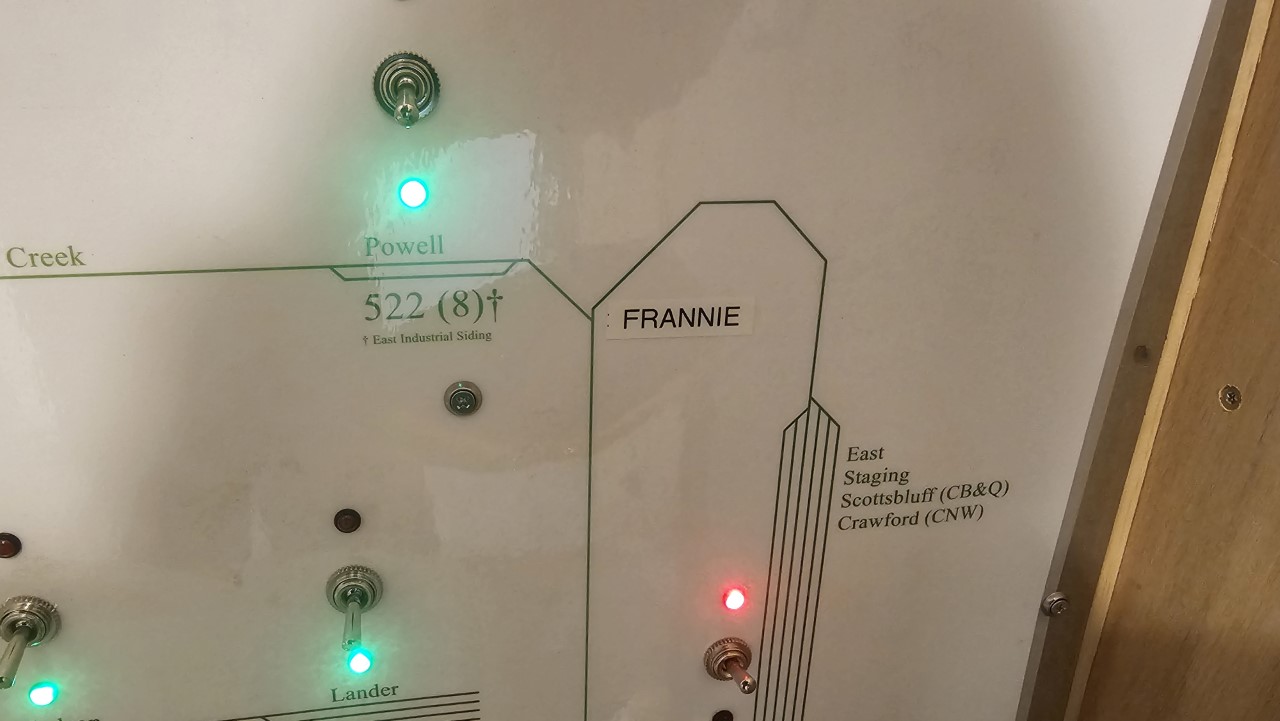

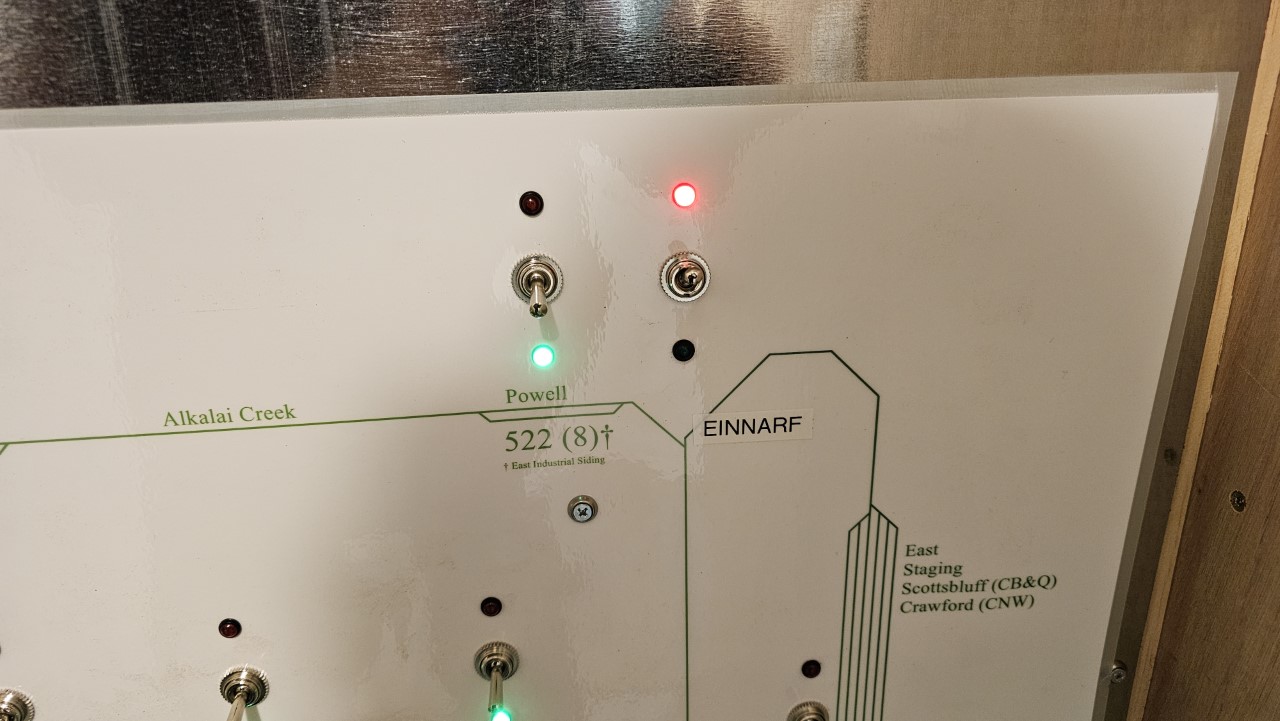

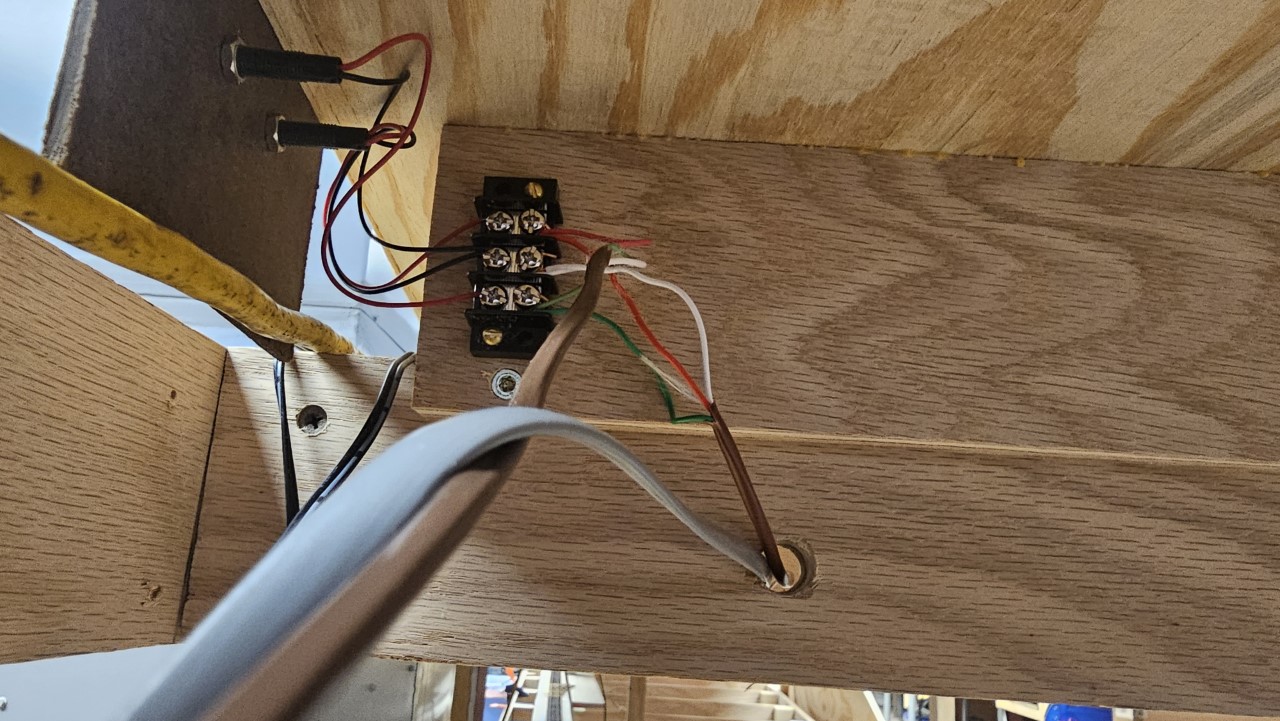

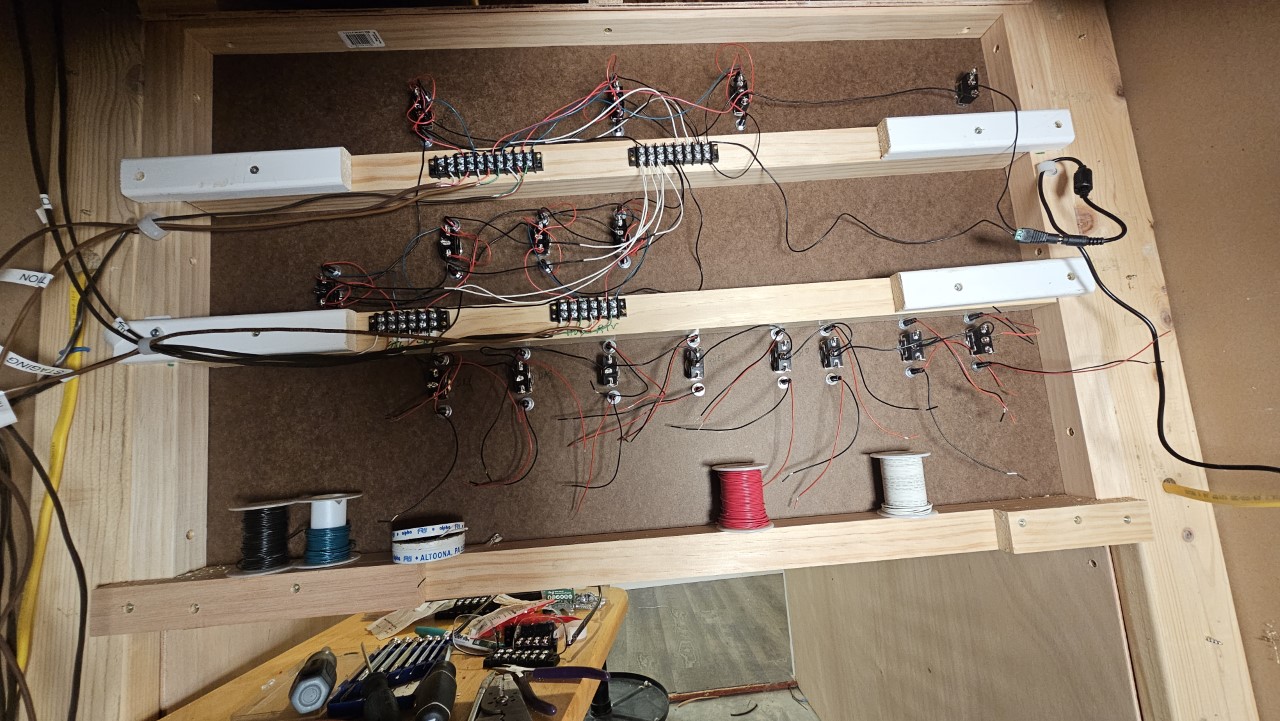

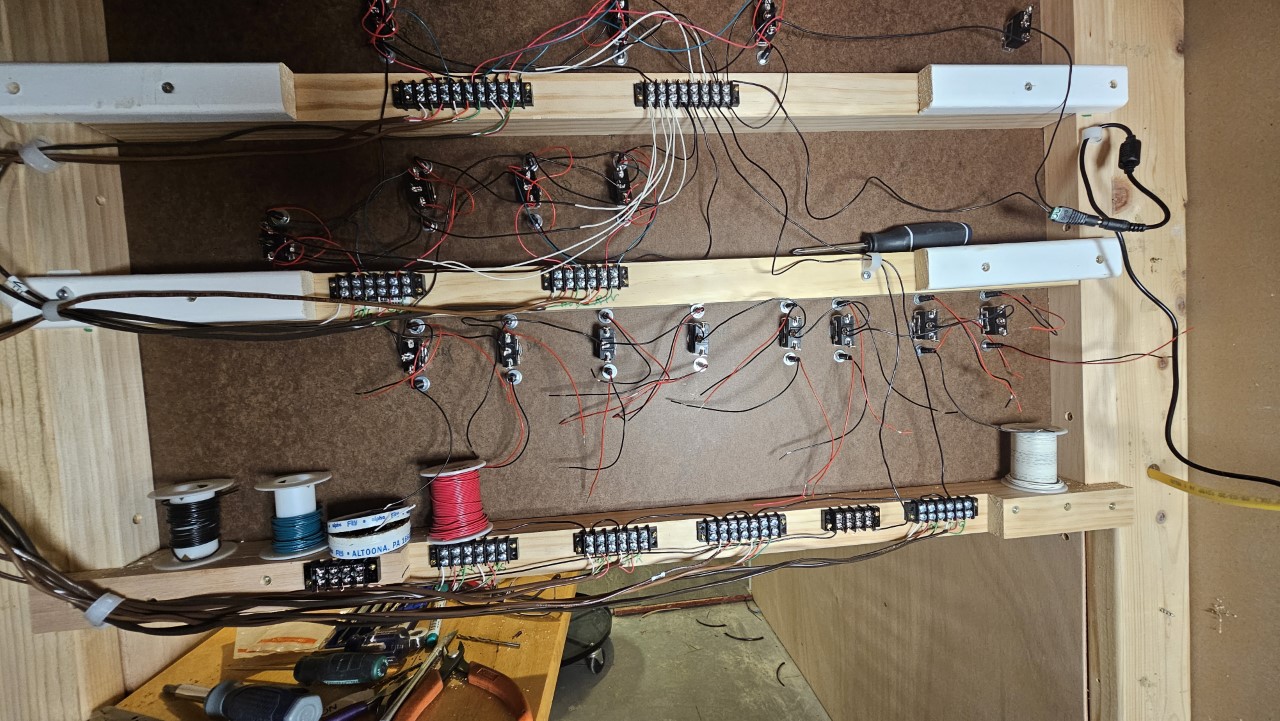

Then it was time to start wiring the panel. I had to crawl into that very confined space behind the panel and sit on a step stool to do the work. I spent a total of probably ten hours back there over about a week. Here the first set of signals is wired in and I'm testing that it actually works before proceeding on with the rest.

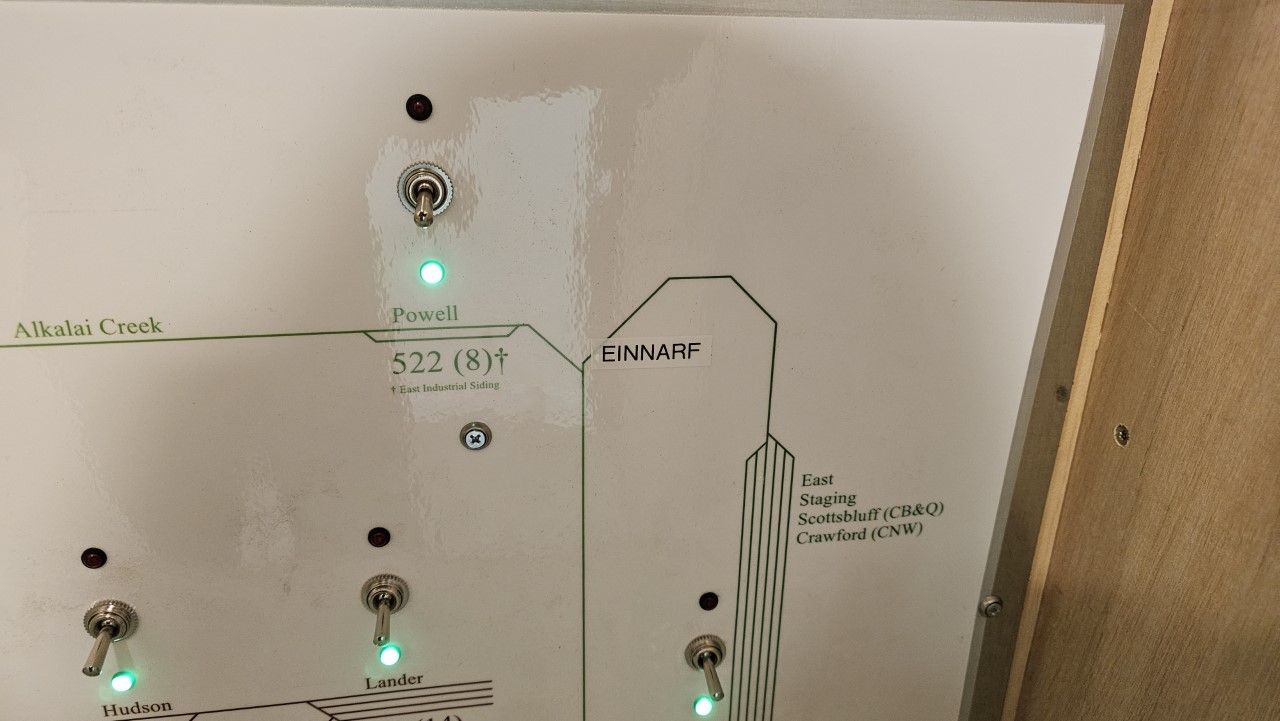

One late addition to the system was designation of the switch taking the Cody branch off the line to East Staging "Frannie." A new set of signals will be installed for that. Calling that turnout Frannie confused the heck out the dispatcher - that junction real life comes off the west end of the Casper division, so on the layout that would lead to West staging.