Casper Construction Progress Part 3 – 2021 – July through September

4 July 2021

It's been awhile since I did an update, and quite a bit has happened in the last five weeks, so here we go...

On June 1st I started messing around with creating a panorama of Casper Mountain for the backdrop behind the yard. This is my first experiment - a single shot taken with my cellphone camera in panorama mode. This was taken from Amoco Park in Casper, the site of the old Standard Refinery. This is a reduced resolution shot - the original is a pretty big file.

On 3 June I posted my monthly update video on YouTube.

Then I moved on to the ladder turnouts themselves. I proceeded very slowly and cautiously here, since I didn't want to mess up operation of the turnouts with the ballast and glue. I also had to make several over-center springs to replace the ground throws I'd originally installed. I spent most of the rest of the time on the layout for the month ballasting the ladder and adjacent tracks.

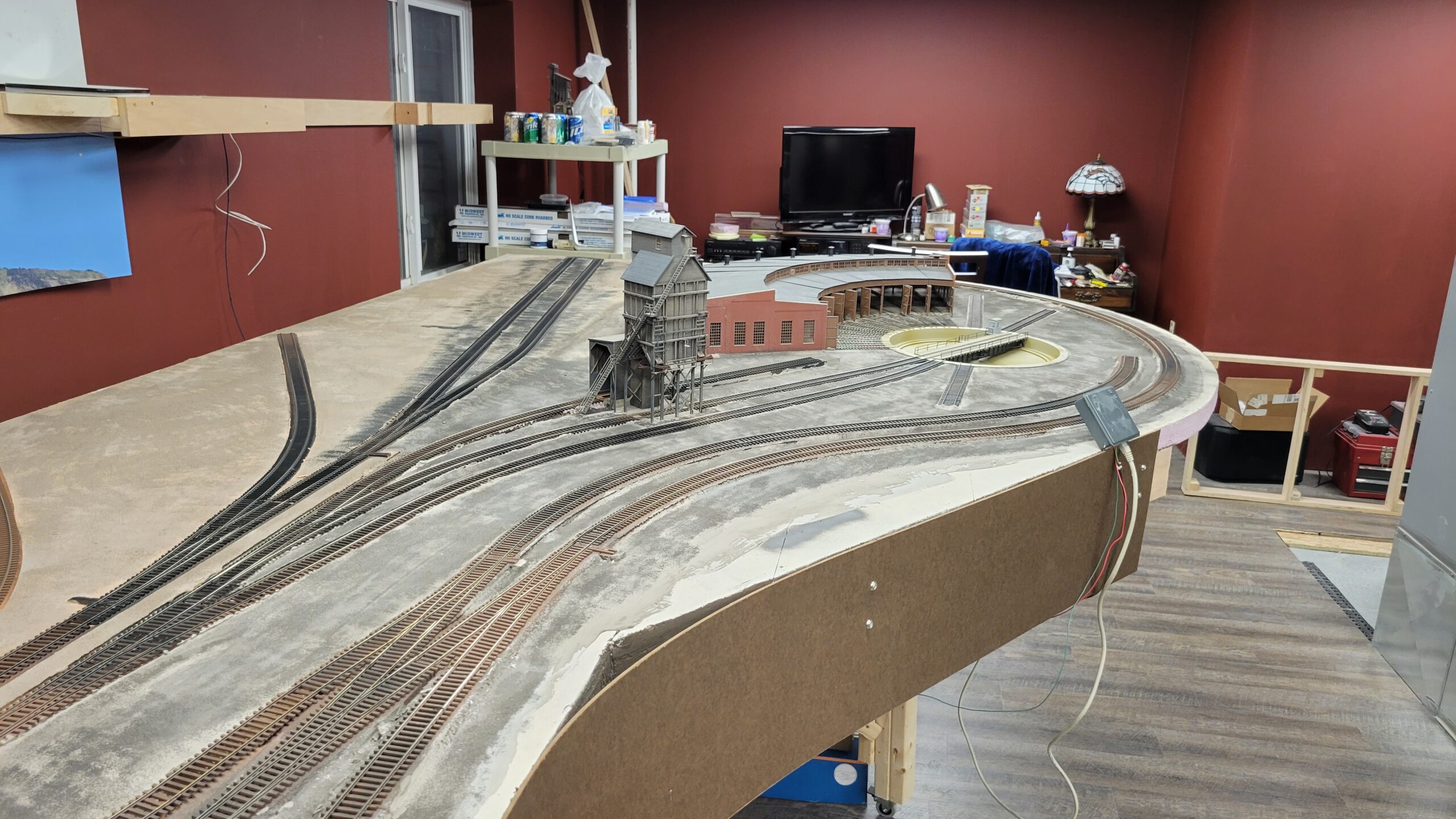

Today I installed the second turntable lead - the one that goes through the coaling tower. The only track left to complete in Casper yard is the service track for the coaling tower, sand bin and ash pit. That will be added in the next day or two, and after that I'll wire up the new tracks and begin finishing this section.

I did just a little bit of work on Rocky Mountain Drilling, adding frieze boards along the roof line and fabricating the loading platforms. Here's the building set in place, with the platforms sitting loosely alongside. Work has stopped at this point until I can get lighting installed. Parts for that are on order and should arrive in a week or two.

I've also continued working on the panorama for the backdrop. Casper yard is 24 feet long, and the mountain needs to extend across that entire distance. On June 20th the weather was right, so I spent several hours travelling across the town taking many photos of the mountain. I've built several test panoramas, and while none have been of sufficient quality to use as the final product, I'm getting there. I'm hoping to have the backdrop at least ready for final printing by the end of July.

The panoramas are way to large to post here (several hundred megabytes each), but here's a photo that representative of the what's going into it.

June 25th was the first anniversary of beginning construction of this layout, so on that day I posted a "First Birthday" video.

And finally, yesterday I posted my July construction update video

8 July 2021

Here the last track - the commodities delivery track - is in, running through the coaling tower delivery shed.

The pink foam block that's partially visible at the right edge of the photo matches the footprint of the sand bin and drying house that will be placed about there. The gondola is roughly in position to deliver sand. The end of the track extending towards the camera is where a gondola will be positioned for the ash hoist to empty into it.

Here are the Standard Refinery oil loading tracks - also with a first coat of brown.

The entire area, especially the refinery tracks, will get a second coat of black paint, ranging from light near the yard ladder to somewhat heavier in the engine facility, and very heavy on the loading tracks, where years and years of oil spillage will have turned the ground black.

15 July 2021

8 August 2021

It sat rolled up like that because I had to finish preparing the skyboard. Some of the seams had cracked a bit while it was rolled up after being removed from the New Jersey layout. I patched the seams using Squadron White putty and, when that ran out, Testors plastic filler.

I also filled all the nail holes and sanded everything smooth.

I also filled all the nail holes and sanded everything smooth.

I spent a couple hours putting together a new sanding station, replacing the TV tray I was using as sander stand with a old stereo cabinet I found at a thrift store for just a couple of bucks. I built a new top using left over scraps of wood fro the bookcase project in the library, and had a much improved place to work!

On August 1st I published Episode 6 of Building Casper, which covers laying track in the classification area.

On the 3rd of the month, I published my usual layout update video.

On the 6th I tried my hand at soldering leads to tiny little LEDs for the lights above the doors for Rocky Mountain Drilling. Much to my surprise, the second LED works! The first one flew off into the ether somewhere, never to be seen again.

These LEDs are really small - they're one millimeter long by half a millimeter wide!

I had to work using a magnifying lamp AND my Optivisor to even begin to see the solder pads. I've since bought a lamp with more magnification power so I can see better.

12 August 2021

19 August 2021

Here's a very short video of some tank cars running back and forth over the switch:

They're a bit bumpy, as I've not cleaned up the ballast and track yet. But things go through the switch just fine!

23 August 2021

A few hours later I went back down to the layout to scope things out and maybe do some more ballasting. I'm glad I did! I had another disaster in process!

The water in the ballast glue apparently soaked into the cork enough to loosen it from the subbase, and it wrinkled severely between the two sets of tracks! Not only that, but the supposedly waterproof caulk let go under the turnout, and it bowed up as the cork wrinkled.

I decided to try to weight everything down in hopes that it will flatten back out as the moisture leaves the cork. I added some full strength yellow glue under the loose edge of the cork and laid a 4' level along the tracks. With the added weight of the soda cans it flattened the switch back out (I hope!) and the thick steel rule from my combination square flattened the edge of the cork.

It will stay like that for at least a full day before I remove it tomorrow night (or maybe Thursday morning). Hopefully everything will be okay. If not, I'll have to pull up this switch and the cork underlayment and relay it.

It will stay like that for at least a full day before I remove it tomorrow night (or maybe Thursday morning). Hopefully everything will be okay. If not, I'll have to pull up this switch and the cork underlayment and relay it.

31 August 2021

I almost forgot that I have to finish the CNW scenery above Casper in the corner before I can set Casper in its permanent home. So I pulled the yard back out and got to work on the area by painting the rails. Here's the painting in progress:

That job is now done, and I can proceed with grass and other foliage in the area.

That job is now done, and I can proceed with grass and other foliage in the area.

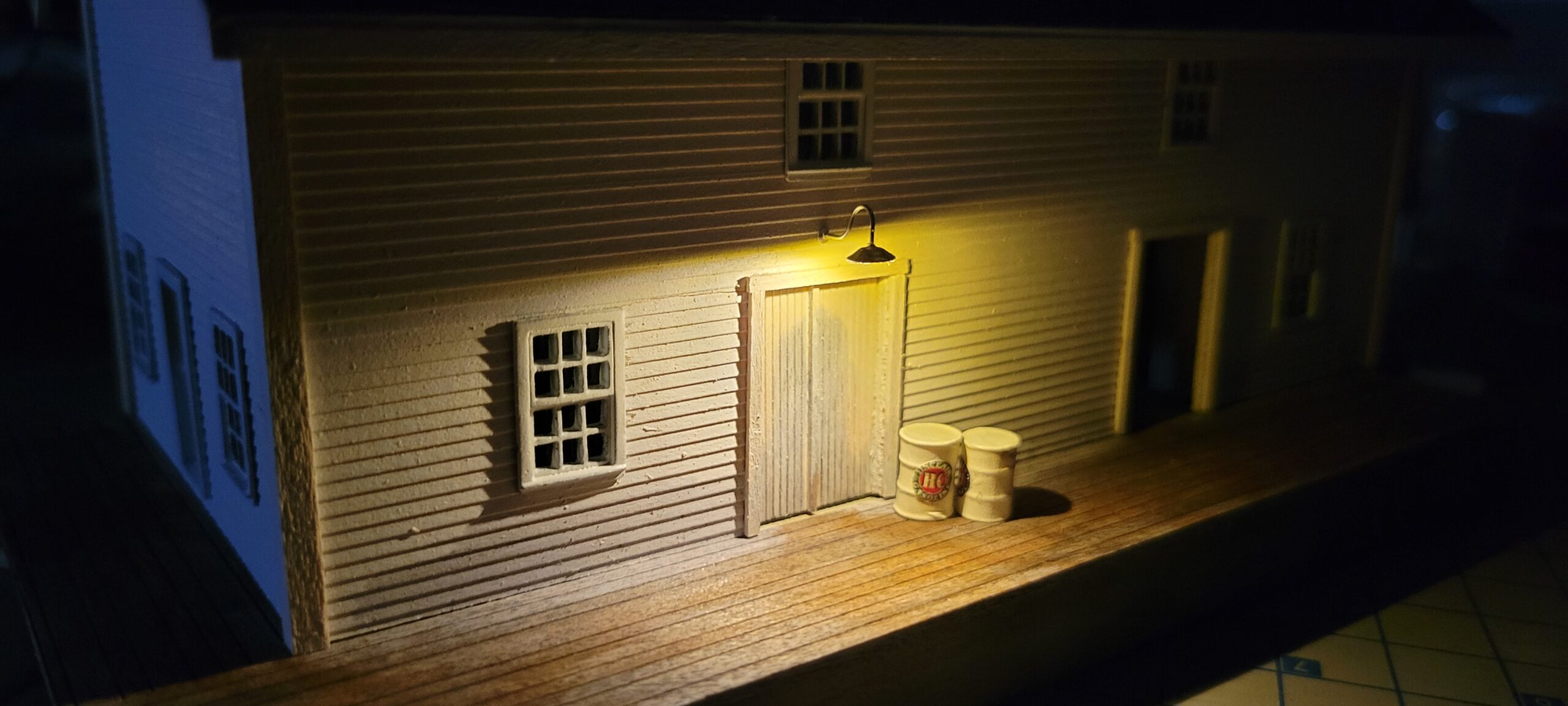

I also finally received the LEDs I need to add lights to Rocky Mountain Drilling. Using .018" outside Diameter tubing, I fabricated this gooseneck lamp, threaded the leads of a pre-wired 0603 LED through it, added the shade and an escutcheon at the building wall, and wound up with this:

This came out better than I hoped! Five more of these and the lighting will be done!

This came out better than I hoped! Five more of these and the lighting will be done!

4 September 2021

The last several days have been spent mostly on Rocky Mountain Drilling lighting. I installed all the exterior lights, then added some scrap thin plywood to the interior to act as light blocks from the upper windows. The idea is that the building is one large warehouse with a loft, open in the center all the way to the roof. No real interior detailing to be done, except maybe sitting a few pallets with crates near the open door.

After the loft baffles were in place, I added a few LEDs to the underside to represent interior lighting. Here's a shot of the inside:

I started connecting all the wiring together. I was concerned that the very fine LED wires would easily break when attached to a heavier wire to run under the layout. After turning it over in my head overnight, I came up with the idea of using scrap bits of PC board ties (the ones I use to make turnouts) to act as connection points for the wiring. I prepped two pieces - one for interior and one for exterior lights (in case I want to adjust the brightness separately). I cut a groove in each bit so that I had two electrically isolated pads on each, then tinned them.

21 September 2021

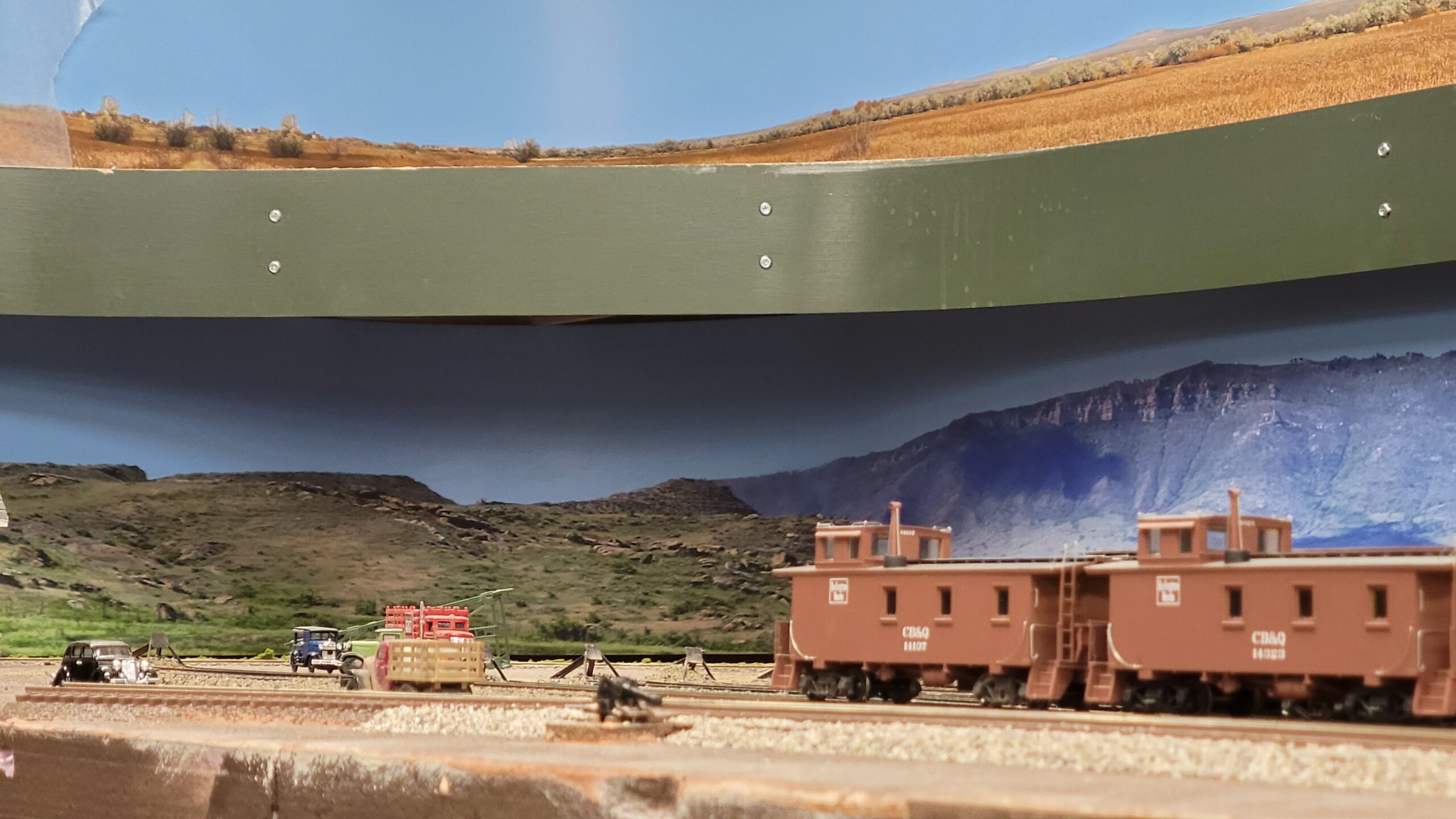

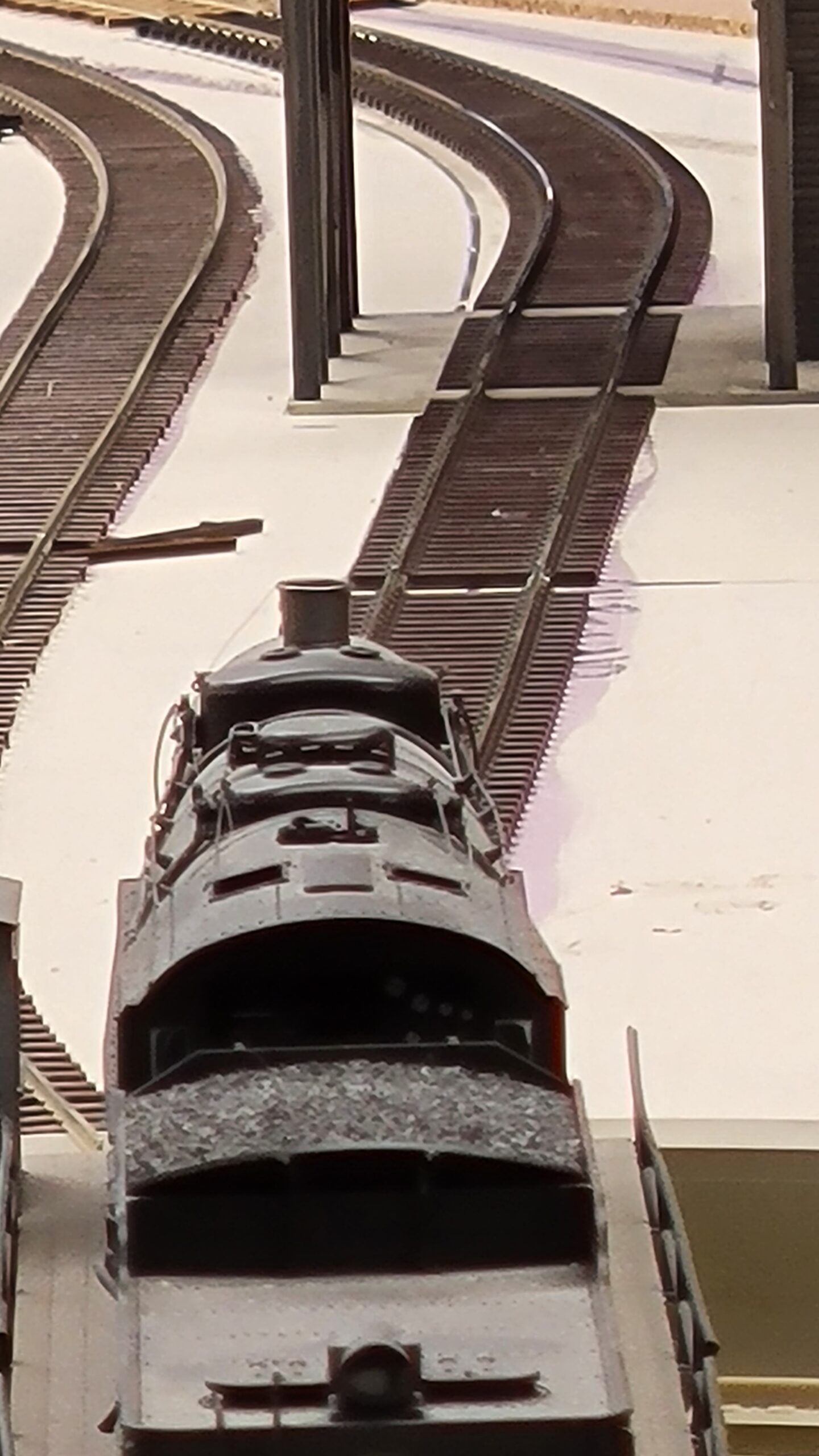

Quite a bit has been happening during the last few weeks. First, right after my last update, I purchased an Osmo Pocket 2 gimbal-stabilized camera. This is a very small video camera, and I was interested in using it to record cab ride videos on the layout. Here's a couple of still photos taken by the camera:

These were taken using the autofocus feature of the camera. The depth of field is not good, and the camera focused on the track about eight inches in front of the lens. But I really DO like the "eye level" of the camera - it's about six scale feet above the ties when the camera is sitting on a flatcar.

These were taken using the autofocus feature of the camera. The depth of field is not good, and the camera focused on the track about eight inches in front of the lens. But I really DO like the "eye level" of the camera - it's about six scale feet above the ties when the camera is sitting on a flatcar.

I did tests of the camera with the focal distance set to one, two, three and four car lengths in front of the lens. I ran a test train with the camera on a flatcar in front back and forth in Casper yard to see how well each different focal distance looked. Those are here:

https://youtu.be/jJoDhgQkW8o

https://youtu.be/HUTxm2nArwA

https://youtu.be/pN504adWvq8

After watching the videos a few times and reading the comments of others, I decided the videos were just not good enough. The camera is not designed for recording miniatures! So I returned it to the store and ordered the older, first version of the camera - the Osmo Pocket. It has a slightly smaller aperture - f 2.0 as opposed to f 1.8. It also has a slightly narrower field of view. I hoped the two would combine to provide a somewhat better image. It also was $150 cheaper - not a small consideration.

Here's a video I made that compares recordings from the two cameras:

I decided that the Pocket was a bit superior to the Pocket 2, and decided to keep it. Depth of focus still leaves something to be desired, but it's not too bad with focus set to 80-120 scale feet ahead of the lens. And the narrower field of view eliminates most of the "lean-in" of the rolling stock that's apparent in the Pocket 2 recordings when seen side-by-side with the Pocket recordings.

With that done I was finally able to get back to the layout.

I'm focusing on the upper deck of the CNW, in the back corner near Hudson, since that's the only thing I have left to finish prior to moving Casper back into it's permanent location in the corner.

I'm trying to make a cornfield in the corner, where the benchwork is wide enough not to just represent the railroad's right-of-way. Not sure I'm doing a very good job, but it will be in the background and with a very limited viewing angle, so I'm not too worried. I picked up a bag of polyfiber at Hobby Lobby and started out by painting some stretched out handfuls brown and orange to match the cornfields on the backdrop.

I've given up on the over-center springs for the turnouts. While they generally worked okay, they're just not reliable enough. They springs tend to pop out, and they're kind of a pain to install. Just a little off and they push a turnout to one side or the other all the time. So I'm going back to the ground throws, this time installing them with ring shank panel nails and caulk to ensure they're stable. I have to drill out the mounting holes to 5/64" for the nails to clear, but when installed they don't look too bad.

23 September 2021

All that's left is to add a couple of 3-D versions of the trees you can see in the backdrop. I already have an idea how to make them. It involves an old wallpaper paste brush and ground foam. But those can wait a few days (or weeks). I think tomorrow I'll move Casper back into its corner and secure it. Over the weekend I may start benchwork towards Powder River!

All that's left is to add a couple of 3-D versions of the trees you can see in the backdrop. I already have an idea how to make them. It involves an old wallpaper paste brush and ground foam. But those can wait a few days (or weeks). I think tomorrow I'll move Casper back into its corner and secure it. Over the weekend I may start benchwork towards Powder River!

Boy, that fascia sure needs cleaned, doesn't it?